For manufacturers of high-performance aluminum profiles, achieving consistent T6 temper is the greatest hurdle to profitability. Minor deviations in the industrial heat treatment process often result in catastrophic quality failures—unacceptable warpage, inconsistent strength, and spiraling production costs from high scrap rates. The most critical component for T6 integrity is often the precise control offered by the aluminum extrusion line’s final aging furnace.

The path to superior material performance and maximized yield is paved with absolute control over the precipitation hardening phase. This requires an integrated, high-precision system that manages thermal stress from the extrusion press to the final stacking.

Guangdong Pinrui Machinery Co., Ltd., a high-end custom equipment supplier since 2009, leverages over a decade of specialization to deliver solutions that are proven and trusted worldwide. This guide explores the four non-negotiable factors for reliably achieving T6 standards and successfully hardening your aluminum.

I. The True Cost of Inconsistent Aluminum Profile Hardening

Metallurgical Requirements for Aluminium Hardening

The core purpose of the final T6 process is to achieve high yield strength in profiles, making them certified age-hardened aluminum. This strength relies entirely on controlled precipitation. If the process fails, the material requires additional processing or becomes scrap.

- Understanding T6 Integrity: While some strength can be gained via cold deformation, true T6 certification—essential for structural stability—is only achieved through the final, controlled thermal process. Any failure during this initial quenching treatment or the final aging directly jeopardizes the entire batch and increases production costs.

Minimizing Warpage and Strain for Higher Yield

The post-extrusion process introduces significant variables that inflate the scrap rate:

- Warpage from Quench: Thermal shock during the rapid cooling phase creates internal stresses leading to profile distortion.

- Over-Straightening Damage: Aggressive post-quench straightening (used to fix warpage) induces secondary strain hardening, which can lead to fatigue failures and requires another quenching treatment or scrapping.

- Furnace Uniformity: A poor aluminum aging furnace creates products with inconsistent properties in the same batch, failing the T6 standard.

II. Precision Downstream Control: Quenching and Pulling

Achieving high-quality T6 aluminum is a continuous, high-speed process. Pinrui’s expertise lies in eliminating process variability between the press and the aging furnace.

Mastering the Critical Online Quenching Phase

The rapid cooling step, or quenching metal, is non-negotiable. If the transfer time from the die to the cooling medium is too slow, the profile cannot achieve its maximum potential strength.

- Pinrui’s Solution: We offer high-speed online quenching technology designed to guarantee the critical cooling rate is met for all profiles. Our systems integrate seamlessly with any specialized quench furnace setup. You can explore the mechanics of what is quenching and the required control systems for how to achieve precision online quenching control in our technical guides. We also contrast the thermal differences between steel vs. aluminum quenching.

Active Stress Management with Full Servo Puller Systems

Warpage is primarily a result of thermal stress. Pinrui’s technology actively manages this stress instead of aggressively correcting it later.

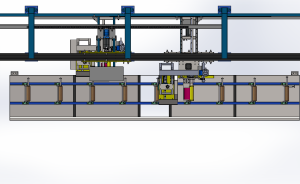

- Precision Pulling: Our advanced full servo puller technology—including the high-efficiency alternating full servo puller and robust twin head double saw puller—applies precise, dynamic tension immediately upon exiting the press. This active management minimizes thermal distortion.

- System Options: Whether you need a sophisticated alternating full servo puller for high-speed operation, an automatic puller, or a powerful single puller system, Pinrui’s equipment drastically reduces the need for aggressive post-straightening, thereby safeguarding the material integrity. Learn more about the specific twin head double saw puller features and our other automatic puller and single puller and twin head double saw puller options.

III. The Core Quality Factor: Precision Aluminum Aging Furnace Technology

The final, critical stage of T6 hardening is precipitation hardening inside the aluminum aging furnace. This process, known metallurgically as ageing of metals, dictates the profile’s final mechanical properties.

Guaranteeing Uniformity for Consistent T6 Temper

Temperature stratification (hot spots and cold spots) within the furnace is the primary cause of inconsistent strength and high scrap rates. Profiles located in different parts of the furnace can be over-aged (brittle) or under-aged (soft) in the same cycle.

| Problematic Furnace Feature | Material Defect | Impact on Production Costs |

| Non-Uniform Temp | Mixed under-aged and over-aged profiles. | High scrap rate, warranty failures. |

| Inaccurate Temp Control | Incorrect T6 strength; material requires further treatment. | Product failure, material waste. |

Pinrui’s Multi-Zone Furnace Advantage

Pinrui’s customized solutions, including the standard aging furnace and the rapid drop bottom furnace, are engineered for maximum temperature stability.

- Uniformity Control: Our multi-zone systems, combined with optimized airflow, ensure a temperature variance of ±3°C or better throughout the heating volume.

- Process Consistency: This consistency ensures every section of every profile achieves the precise precipitation phase required for true T6 hardening, eliminating inconsistencies often associated with tempered steel processes. We offer solutions for processes ranging from T6 hardening to annealing aluminium and understanding the differences between annealing vs. tempering.

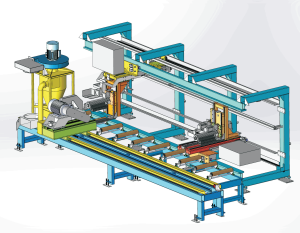

IV. Integrated Extrusion Line Automation

High-volume, high-quality manufacturing requires a fully automated, seamless flow. Pinrui provides advanced equipment for every step of the aluminum extrusion line:

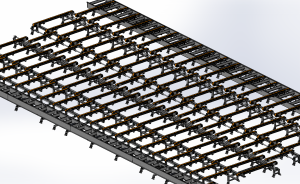

- Cooling Beds: Profiles move seamlessly from the quench area onto our reliable belt type cold bed production line or the dedicated translational type cooling bed production line.

- Precision Cutting: Accurate sectioning is achieved with the finished products saw saw gauge system, and precise measuring is guaranteed by the finish saw and saw gauge system machine.

- Final Handling: Our automatic handingtable production line and integrated automatic stacker ensure minimal human error and efficient transport of the finished, T6 hardened profiles to storage.

V. Unlock Guaranteed T6 Performance Today

In the competitive landscape of aluminum manufacturing, high scrap rates and inconsistent quality are unsustainable. Investing in a precision aluminum aging furnace and advanced automation equipment from Pinrui is an investment in guaranteed quality, higher profits, and reduced production costs. Achieve true T6 strength consistently.

Stop absorbing the high cost of T6 failure.

We invite you to reach out to our team. Tell us about your most persistent T6 quality challenge—be it warpage, inconsistent hardness, or high residual stress. Visit our contact us page today for a customized technical roadmap that shows exactly how Pinrui’s patented equipment will solve your problem and dramatically increase your material yield. Visit our homepage to learn more.