The T6 temper represents the pinnacle of aluminum structural integrity. Yet, achieving consistent, high-yield T6 aluminum often feels like a gamble. You’ve invested significant capital in a top-tier electric heat treatment furnace, but are still facing scrap rates up to 10% due to strength failures or dimensional warp. This is a profit drain.

The critical insight is this: the industrial heat treatment furnaces or furnace oven provides the metallurgical potential, but the post-furnace automation determines the final certified quality and, ultimately, your profitability. For general context on this sector, see our page on industrial heat treatment.

At Pinrui Machinery, we specialize in this critical interface. Since 2009, we’ve developed the intelligent link machines that solve these problems. With 24 patents in core extrusion line technology and equipment exported to over 30 countries, we turn your thermal investment into guaranteed, high-yield output. You can explore our core solutions on our main website.

I. Pain Point Analysis The Two Major Cost Killers in Heat Treatment

H2: Strength Loss Caused by Uneven Heat Treatment Furnace Temperature

Why does T6 strength sometimes fall short, even when your expensive furnace reports the correct setpoint temperature? The issue lies in temperature uniformity within the furnace chamber itself.

Even expensive SHT (Solid Solution Heat Treatment) quench furnace systems struggle with internal thermal gradients. A variation of only a few degrees can prevent the complete dissolution of alloying elements, resulting in a profile that can never reach its maximum T6 strength potential—regardless of the subsequent handling. This non-uniformity is a silent killer of quality and requires precise control.

We believe that every component entering the furnace should be presented optimally. Our systems ensure profiles are loaded correctly, maximizing the heat transfer efficiency of your electric heat treatment furnace.

H2: Quench Distortion and Stress The Root Cause of Scrap

Are excessive shape failures and rework hours stealing your profit after the profiles exit the furnace? The moment the hot aluminum exits the industrial heat treat furnace and is subject to rapid cooling, it undergoes intense thermal shock. This is the quenching treatment—a necessary process that creates the structural strength but also introduces severe internal stress and profile warping. For an overview, see our discussion on the quenching treatment.

This quench distortion and stress is the number one cause of costly scrap and rework. If your focus is on achieving maximum aluminium hardening, you must first master the art of controlling this distortion.

Furthermore, the quenching metal process is time-sensitive. Any delay between the furnace and the quenching medium—known as the quench delay—can be fatal to the final T6 strength. If you want to know more, you can read about what is quenching.

II. Core Value and Control in the Furnace Stages

H2: The Critical Role of the SHT Heat Treat Furnace Securing T6’s “Initial Capital”

The SHT heat treat furnace is where the metallurgical transformation begins. For complex or high-strength alloys, the type of furnace oven—continuous or batch—must be carefully selected.

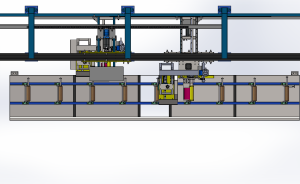

Whether you use a large-volume continuous system or a specialized quench furnace, the efficiency of the thermal cycle is paramount. Our complimentary automatic puller and automated loading systems ensure that profiles are spaced and aligned perfectly, guaranteeing the internal air circulation works optimally. This uniform positioning helps secure that vital “initial capital” of uniformly solid-solutionized material.

H3: The Function of the T6 Ageing Heat Treatment Oven Finalizing Strength

Following the successful quenching, the profile enters the heat treatment oven for artificial ageing furnace treatment. This low-temperature soak finalizes the T6 properties by allowing strengthening precipitates to form.

The precise control of time and temperature here is critical. Even slight deviations can lead to “over-ageing,” resulting in an immediate reduction in the required T6 strength for your age-hardened aluminum. You might also want to compare this process with annealing aluminium.

For specialized components or small production runs, a small heat treat oven provides the necessary flexibility. Properly controlled, the ageing step locks in the structural properties achieved during the rapid cool-down process. This is the final stage of ageing of metals.

III. Post-Furnace Control The True Guarantee of High Yield

This phase is Pinrui’s core domain. We transform volatile post-extrusion heat into dimensionally stable, certified T6 profiles.

H2: Online Quenching The Balance Between Speed and Uniformity

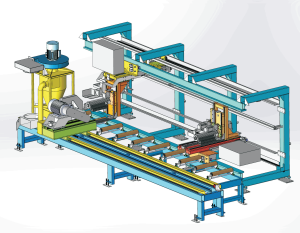

How can you meet the critical cooling rate while guaranteeing every part of a complex profile cools uniformly? Meeting the critical cooling rate is the main challenge of quenching metal. Our online quenching systems are designed not just for speed, but for precise uniformity across complex profiles. You can learn how to achieve precision online quenching control with our technology. For a comparative study, see our article on steel vs aluminum quenching.

- Advanced Control: Our online quenching equipment offers multi-zone, multi-medium cooling. We use a combination of directed water spray, fine mist, and high-velocity air, allowing the operator to tailor the cooling profile to the specific geometry of the extrusion.

- Eliminating Quench Delay: Integrated directly into the extrusion line, our system minimizes the time lapse between the press exit and the cooling medium, mitigating the strength-robbing effects of quench delay. For general background on the treatment, check out the quenching treatment.

H2: Puller Control of Thermal Stress Minimizing Distortion

Is your traditional puller actually causing shape failure by applying uncontrolled tension to hot metal? A profile that exits the industrial heat treat oven is soft, hot, and highly susceptible to mechanical forces. The greatest source of post-quench distortion comes from uncontrolled tension applied by the puller.

- The Servo Difference: Traditional automatic pullers with fixed-speed settings amplify the thermal stresses induced by online quenching.

- Pinrui Core Advantage: Our patented full servo puller and alternating full servo puller systems are intelligent. The system monitors the profile’s temperature and contraction rate, then dynamically adjusts the pulling force, effectively counteracting the thermal stress. This intelligent control minimizes profile deformation, keeping it in the sub-millimeter range. For single-line operations, our single puller provides superior control. For high-volume lines, the twin head double saw puller (which you can read more about in twin head double saw puller features) ensures continuous operation with minimal stress.

IV. Advanced Techniques and Dispelling Common Misconceptions

H2: Common Misconceptions Dispelling Three Myths about Heat Treat Ovens

To operate efficiently, you must look past common industry myths regarding your thermal assets.

- Myth 1: Bigger is Always Better for Production: Focusing solely on furnace size overlooks the operational cost. Using a drop bottom furnace for specialized batches may be more efficient than running a massive unit at half-capacity.

- Myth 2: Temperature is the Only Variable that Matters: This ignores the crucial role of airflow. You should also be aware of the difference between annealing vs tempering in different metal processes, and how that relates to T6.

- Myth 3: The Small Heat Treat Oven is Only for R&D: Smaller furnaces are vital for manufacturing flexibility. They allow for rapid changeovers, specialized alloys, or running small, high-margin orders.

H2: Future Trends IIoT and the Intelligence of Industrial Heat Treatment Furnaces

Are you ready to use data and AI to predict and prevent T6 strength failure before it happens? The future of high-yield aluminum is predictive and integrated. Industry 4.0 demands that the data from the industrial heat treatment furnaces be instantly linked to the mechanical equipment.

- Data-Driven Quality: Systems are connecting data from the furnace, the online quenching system, and the full servo puller. This creates a comprehensive profile of the T6 process.

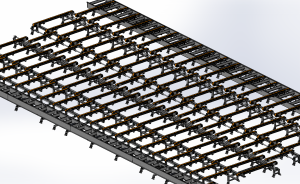

- Predictive Maintenance: AI monitors variables across the line, from the automatic handing table production line to the translational type cooling bed production line. This allows for real-time, closed-loop adjustments to your process. The finish saw and saw gauge system machine and the finished products saw saw gauge can instantly verify the final dimensions.

V. Action Guide Optimizing Your Heat Treatment Process

H3: T6 Yield Improvement Step-by-Step Checklist

If your T6 yield is lagging, focus your audit on the vulnerable post-furnace phase.

- Audit Your Furnace Uniformity: Verify that your existing electric heat treatment furnace can consistently meet the tightest temperature uniformity requirements.

- Quantify Quench Delay: Use precise timing to measure the delay between the furnace exit and the achievement of the critical cooling rate. You might also want to look into how to achieve aluminium hardening with minimum delay.

- Upgrade Your Interface: If you are using conventional, fixed-speed pullers, seriously consider upgrading to an alternating full servo puller or single puller. This is the single most effective way to manage thermal stress and reduce scrap due to distortion. Implement an automatic stacker for seamless handling.

Conclusion

Maximizing T6 age-hardened aluminum yield is a sophisticated process that requires total control over both heat and mechanical stress. The sheer power of your heat treatment furnace must be harnessed by intelligent automation. For a strong comparative example in another material science, consider the principles of tempered steel.

Pinrui Machinery, established in 2009, stands ready as your partner in this endeavor. Our investment in 24 patents—focused specifically on the automation that manages the post-furnace environment—has been proven in over 30 export countries to substantially lower scrap and guarantee quality. We don’t just sell machines; we sell guaranteed T6 yield.

Ready to convert your thermal potential into tangible profit? Don’t just ask for a brochure. Request a personalized T6 Yield Improvement Assessment—a low-friction consultation that shows you exactly how our patented full servo puller and twin head double saw puller technology can boost your quality and substantially lower your scrap costs. Contact us for a custom solution today.

Frequently Asked Questions (FAQ)

Q: What is the main difference between a heat treatment furnace and a heat treat oven?

A: A heat treatment furnace usually refers to the SHT (quench furnace), which operates at high temperatures (500°C+). A heat treat oven or ageing furnace operates at lower temperatures (around 170-200°C) and is used for the final stage of aluminium hardening.

Q: How does Pinrui’s equipment work with my existing industrial heat treatment furnaces?

A: Pinrui’s equipment, including the full servo puller and automatic puller, are modular systems designed to integrate seamlessly with any brand of electric heat treatment furnace or extrusion line. We optimize the handling and cooling processes, which are typically the weakest links.

Q: Why do I need a full servo puller if my industrial heat treat oven is state-of-the-art?

A: The industrial heat treat oven provides the necessary heat for aluminium hardening, but the profile is highly unstable when it leaves. A traditional puller causes stress and distortion. A full servo puller uses dynamic control to actively minimize this distortion caused by the thermal shock of online quenching, guaranteeing the profile remains straight for the next stage of the translational type cooling bed production line.

Q: What is the risk of “quench delay” and how does online quenching solve it?

A: Quench delay is the time lag between the profile exiting the industrial heat treat furnace and reaching the critical cooling rate. Even a few seconds of delay can prevent the alloy from achieving full T6 strength. Online quenching eliminates this risk by immediately applying the cooling medium, often in a multi-zone format, as the profile leaves the press.

Q: How can I initiate a T6 Yield Improvement Assessment?

A: Simply click the Contact Us link on our website. We will schedule a low-friction consultation to benchmark your current scrap rate and show you the projected yield improvements achievable with our patented automation technology.