0. Introduction The Quality Challenge from Aluminium Extrusion Parts to Extrusion Accessories

The global market for aluminum components, from structural beams to specialized aluminium extrusion accessories, demands unprecedented precision and consistency. Manufacturers and end-users of aluminium extrusion parts face a critical dilemma: how to meet ultra-tight tolerances while simultaneously lowering the per-unit production cost.

The true source of quality and cost variance lies not just at the press, but in the downstream processing known as the cold end. This stage is plagued by the dual challenge of eliminating internal residual stress and mitigating the crippling Finishing Line bottleneck caused by antiquated equipment.

This technical guide establishes a clear link between the precision of cold-end machinery—like those developed by Pinrui Machinery, backed by 24 patents—and the ultimate performance and reliability of every extruded part you produce or consume. We will show how process control, leveraged by fully automated finishing line integration, is the long-term solution.

1. Part I Defining Extruded Aluminum Parts Applications and Quality Requirements

Understanding the demanding applications of modern extruded aluminum parts is crucial before discussing manufacturing solutions. The quality bar has never been higher.

1.1 The Product Spectrum From Standard Profiles to Aluminum Frame Parts

Extruded aluminium serves as the backbone for countless industries. The term covers a wide spectrum, ranging from standard profiles to highly customized components used in everything from electric vehicle battery trays to large-scale photovoltaic systems.

Whether you are producing light-weight aluminum frame parts for robotics or heavy-duty extruded aluminum strut for industrial automation, the structural integrity of the final product hinges on precision finishing. Aluminum’s strength-to-weight ratio makes it the material of choice, but only if its dimensional stability is guaranteed.

The demand for high-quality extruded aluminum hardware is particularly intense. These components often serve as structural connectors where dimensional stability is non-negotiable, especially in assemblies where multiple pieces of extruded parts must align perfectly.

1.2 Quality Determinants for High-Performance Extruded Aluminum Hardware

The performance of all aluminium extrusion products is measured by three non-negotiable quality metrics, all of which are directly controlled by the finishing line equipment.

Straightness and Tolerance: Deviation (twist, bow, camber) is unacceptable for high-speed machining. Dimensional stability ensures that the extruded aluminum parts meet stringent industry standards, requiring strict adherence to tolerances measured at the finished products saw saw gauge and throughout the line.

Surface Integrity: Scratches and handling marks degrade the product and mandate expensive rework. Automation is the only reliable path to prevent superficial damage to delicate aluminium extrusions, ensuring a pristine finish before they move to secondary processes like anodizing or coating.

Material Properties: Proper heat treatment, specifically quenching treatment, is essential. Effective aluminium hardening ensures the extruded parts achieve the specified mechanical strength required for their end use, dictating everything from yield strength to fatigue resistance.

2. Part II Tracing Defects in Extruded Aluminum Parts Residual Stress and Finishing Line Bottlenecks

The most common reasons for costly rejects and lost productivity can be traced back to two fundamental issues at the cold end. These issues are often overlooked until they become critical failures.

2.1 Residual Stress The Silent Killer of Profile Integrity

Residual stress is the number one enemy of dimensional stability in aluminum. If the stress is not fully released, it can cause extruded parts to warp months after production or fail under minimal load during CNC machining. This is a common pain point for manufacturers.

The root cause is uneven cooling during quenching metal. When the outer shell of the profile cools faster than the core, internal forces are created. Understanding what is quenching and the differences between steel vs aluminum quenching is the first step in addressing this.

The tension stretching phase is where this stress is released via controlled plastic deformation. Only precise, powerful, and synchronized equipment can ensure zero-stress results for profiles destined for the ageing furnace. This is critical for applications demanding high geometric precision.

2.2 The Efficiency Tax High Labor Cost for Manual Stacking

Manual operations in the finishing area are the primary cause of operational drag and high manufacturing expenses. The reliance on human hands creates a capacity ceiling and high operating expenditure that undermines the efficiency of the entire line.

The high labor cost for manual stacking includes wages, turnover expenses, and safety risks. This direct cost makes high-volume extrusion parts manufacturing less competitive, especially against highly automated foreign producers.

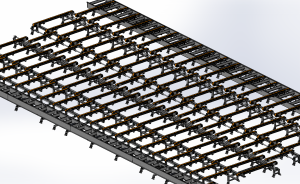

Manual stacking speeds are inconsistent and low. The throughput of the entire line, including the belt type cold bed production line, is limited by the speed of the last two human operators, creating the persistent Finishing Line bottleneck.

Fatigue leads to dents and scratches on aluminium extrusion accessories, increasing scrap rates and reducing profitability. This human element introduces unpredictable quality fluctuations that modern manufacturing standards cannot tolerate.

3. Part III Pinrui’s Solution Equipment Upgrades for Superior Extrusion Parts Quality

Pinrui Machinery addresses these challenges by replacing human variability with machine precision, ensuring that every extruded part meets the highest standards using patented technology.

3.1 Zero Stress Leveling with the Full-Servo Puller

The most critical step in achieving zero-stress extruded aluminium profiles is the tension stretching phase. Pinrui champions servo technology to deliver unparalleled control and consistency.

Our full-servo puller systems eliminate the pressure fluctuations common in older hydraulic setups. Servo drives provide instantaneous, closed-loop feedback, guaranteeing a constant, uniform stretching force that thoroughly releases residual stress. This level of precision is unmatched.

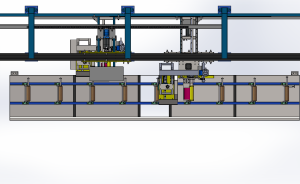

For maximum efficiency, the alternating full servo puller provides continuous traction, ensuring no production breaks, even at high press speeds. This continuous process is essential for lines pushing maximum capacity.

The precision of the automatic puller allows safe handling of diverse profiles. Whether it’s a delicate, thin-walled aluminum frame part or a robust, heavy industrial profile, the system adapts, minimizing waste and damage.

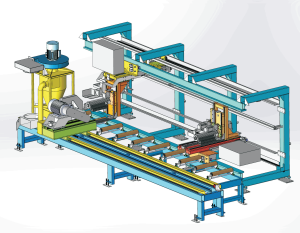

3.2 Automation Eliminates the Finishing Line Bottleneck

Automation at the cold end is the only way to break the capacity ceiling and achieve a rapid robot stacking system ROI. It is a necessary investment for scale.

Transitioning to an automatic stacker immediately eliminates the labor bottleneck. The robotic system maintains consistent speed and placement accuracy, protecting the surface finish of aluminum extrusion accessories and ensuring organized stacking.

Pinrui’s specialization lies in fully automated finishing line integration. This ensures a smooth flow from the cooling bed to the finish saw and saw gauge system machine and then to the final packaging system, all synchronized via a central control system.

Whether you require a flexible single puller setup for smaller lines or the continuous output of the twin head double saw puller for high-speed operations, our systems are scalable to your production volume. The fully automated automatic handingtable production line connects these components seamlessly.

4. Part IV ROI Analysis Reshaping Extrusion Parts Cost and Competitiveness

The decision to invest in advanced finishing equipment is not an expense; it is a rapid capital investment that fundamentally changes the cost structure of every extruded aluminum part produced.

4.1 Quantifying the Robot Stacking System ROI

Calculating the return on investment for an automated system is straightforward and compelling, focusing on both direct and indirect benefits.

The first-order return comes from the elimination of the high labor cost for manual stacking. In multi-shift operations, this saving alone can drive a payback period as short as 1.5 to 3 years, confirming the rapid robot stacking system ROI.

Reduced scrap from handling damage translates directly into higher realized revenue per ton. Automated, precise stacking systems, coupled with consistent online quenching technology, minimize material loss and improve profitability.

By operating at the full mechanical speed of the press, the investment includes a significant capacity uplift. This allows for immediate growth in output of extruded aluminum parts without the need for additional presses.

4.2 Customization and Global Expertise

Success in the aluminum market requires technology that can adapt to unique profile geometries and diverse client demands.

Pinrui’s commitment to providing tailored solutions ensures the optimal design aligns perfectly with your portfolio, whether you are dealing with common extruded aluminum strut or highly complex multi-cavity profiles. We believe customization is the key to maximum efficiency.

With systems operating in over 30 export countries globally, our technology is internationally validated. This experience, combined with our 24 patents in innovation, ensures reliable, long-term performance and technical support for every client.

5. Part V Future Outlook and Practical Checklist

The future of extrusion parts manufacturing is centered on intelligent control and connectivity, pushing the industry towards true Industry 4.0 standards.

5.1 Industry 4.0 and Intelligent Manufacturing of Extruded Aluminium

The next wave of efficiency involves integrating process data from the cold end back into the upstream control systems, creating a fully adaptive production line.

The automatic handingtable production line and saw systems utilize IIoT sensors for real-time monitoring, allowing for predictive maintenance that dramatically reduces unplanned downtime. This is crucial for maximizing uptime.

Data on profile straightness from the servo puller can be used to fine-tune the cooling parameters of the online quenching system. This creates a self-optimizing system for producing flawless extruded aluminium, reducing dependence on manual adjustments.

5.2 FAQ for Aluminum Extrusion Accessories Quality

Q1: How does proper stretching prevent later deformation in extruded parts?

Proper tension stretching performs controlled plastic deformation on the profile, releasing all internal residual stress locked in during the quenching treatment. This ensures the profile remains dimensionally stable when cut, machined, or subjected to temperature changes later, minimizing costly rework.

Q2: What is the primary difference between a full-servo puller and a hydraulic puller?

A full-servo puller uses closed-loop electric motors for instantaneous, precise force and speed control, eliminating the pressure spikes and inconsistent motion inherent to hydraulic systems. This leads to dramatically improved consistency and tolerance for aluminium extrusion parts.

Q3: Does the automatic stacker reduce the risk of scratching delicate profiles?

Yes, significantly. A robotic system handles profiles using controlled, programmed movements and specialized gripper surfaces. This eliminates the dragging, dropping, and rough handling common in manual stacking, protecting the surface finish of all aluminum extrusion accessories.

Q4: How quickly can I expect a return on investment for a robot stacking system ROI?

While variables apply, based on industry averages for high-volume, multi-shift operations, the direct labor savings often deliver a positive robot stacking system ROI within 1.5 to 3 years.

Conclusion Invest in Control, Secure Your Competitive Edge

The quality and cost of your extruded aluminum parts are not accidental; they are a direct result of the precision engineered into your manufacturing line. By strategically upgrading to advanced cold-end equipment, you achieve zero-stress quality, eliminate the high labor cost for manual stacking, and permanently resolve the Finishing Line bottleneck.

Are you ready to transform your production line and secure a competitive advantage in the extruded aluminum hardware market? Pinrui Machinery provides the technical expertise and proven solutions—trusted across 30 export countries—to maximize your efficiency and quality.

Contact us today for a consultation, or visit our homepage to explore our technology.