0. Introduction The Rise of Demand for Custom Aluminum Extrusion Services

The manufacturing landscape has fundamentally shifted. From electric vehicle chassis components to specialized robotic arms, modern engineering demands lightweight materials with extreme precision. This surge has fueled an enormous need for highly capable aluminium extrusion suppliers who can deliver complex, high-tolerance profiles, commonly referred to as custom aluminum profiles.

However, the process of finding the right extrusion supplier goes far beyond searching for “aluminum extrusion suppliers near me.” The biggest challenge for procurement teams is distinguishing a standard aluminium extrusion company from a true custom aluminium extrusion specialist.

This guide provides a professional assessment framework. We will reveal the hidden manufacturing indicators—specifically the cold-end equipment—that determine whether an aluminium extrusion company can truly deliver the precision required for your critical projects while maintaining cost efficiency.

1. Part I In-Depth Analysis Technical Challenges and Risks of Custom Aluminum Profiles

The complexity of custom aluminum profiles introduces unique technical hurdles that simple, older production lines cannot overcome. These challenges manifest as crippling defects later in the product lifecycle.

1.1 Strict Cold-End Requirements for Custom Aluminum Profiles

A non-standard, asymmetric profile demands extraordinary control during the finishing stages to ensure long-term structural integrity.

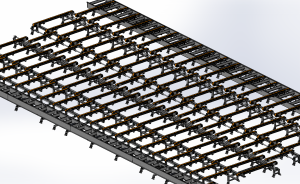

- Stress Relief for Complex Sections: When cooling profiles after the press—a process known as quenching treatment—complex, variable-wall designs are highly susceptible to uneven cooling. This creates significant residual stress within the profile. If this stress is not meticulously relieved, the profile will warp months later or, worse, deform catastrophically during high-speed CNC machining.

- Difficulty of Tolerance Control: Custom aluminum profiles often require tolerances that exceed industry standards by 30% or more, especially when used in modular systems or high-tech devices. The ability of an aluminium extrusion profile manufacturer to hold these tight tolerances is directly related to the stability of their post-extrusion process.

- Interchangeability Standard: Whether for an aluminum extrusion builder creating a solar farm frame or an OEM producing a linear rail, consistency is paramount. Each profile must be perfectly interchangeable with the next, proving the manufacturer has mastered the art of stress-free production.

1.2 Surface Defects How to Affect the Value of Custom Aluminum Extrusion

For high-end custom aluminum extrusion applications, surface integrity is not merely cosmetic; it is functional.

A scratch or dent introduced during the handling process—a common occurrence with high labor cost for manual stacking—can undermine subsequent processes like anodizing or specialized coatings. This defect requires costly rework or, more likely, results in the rejection of an otherwise sound product.

The best extrusion supplier minimizes human intervention. Manual handling, aside from being costly, is inconsistent, leading to unpredictable quality fluctuations. This process inefficiency often creates a severe Finishing Line bottleneck, limiting the maximum throughput of the entire aluminium extrusion company.

2. Part II Evaluation Criteria How to Identify Top-Tier Aluminium Extrusion Company

The elite aluminium extrusion company differentiates itself through technological investment, specifically in the cold end. Pinrui’s equipment serves as the benchmark for this elite tier.

2.1 Puller Technology The Core Capability of Top Aluminium Extrusion Profile Manufacturer

The type of puller an aluminium extrusion profile manufacturer uses is the single most important indicator of their ability to deliver zero-stress, high-tolerance custom aluminum profiles.

- Servo Stretching is the Foundation of Precision: A high-end aluminium extrusion company relies on a full-servo puller. Unlike older hydraulic systems that suffer from pressure spikes and inconsistent force, servo drives use closed-loop feedback to deliver a constant, precise stretching tension. This is the gold standard for reliably eliminating residual stress.

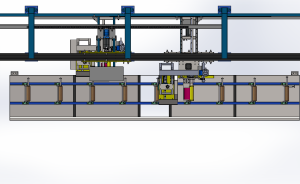

- Continuous Production and Efficiency: For high-volume projects, the alternating full servo puller ensures non-stop traction, maximizing the press utilization and efficiency. Whether they use a robust single puller for specialized runs or a high-speed twin head double saw puller, the underlying servo technology dictates the quality ceiling.

2.2 Level of Automation The Only Path to Resolve the Finishing Line Bottleneck

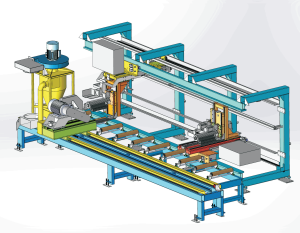

Efficiency and cost control are the ultimate competitive advantages for any extrusion supplier. Automation is the key to unlocking both.

- Efficiency and Cost Control: An automatic stacker instantly eliminates the labor-intensive, costly manual stacking area. This provides a rapid robot stacking system ROI and significantly reduces the per-unit production cost of your custom aluminum profiles.

- Pinrui’s Integration Advantage: Pinrui specializes in fully automated finishing line integration. This means a seamless flow from the cooling process to the finished products saw saw gauge and the automatic stacker. This integrated approach ensures profiles are handled gently, preserving surface integrity and preventing the accumulation of defects.

3. Part III Practical Guide How to Interview Aluminium Extrusion Suppliers

When you are seeking a reliable custom aluminum extrusion partner, move past basic questions about alloy and length. Focus on their operational expertise.

3.1 Supplier Evaluation of Non-Technical Metrics

These factors demonstrate a supplier’s commitment to quality and scale.

- Global Experience and Case Studies: A top-tier aluminium extrusion company should have a global footprint. Pinrui’s equipment, for instance, is trusted in over 30 export countries—a strong indicator that the end-product meets diverse international quality standards.

- Technical Patents and Innovation: Innovation is a proxy for reliability. Ask your potential extrusion supplier about their investment in modern equipment and whether their machinery partner holds patents. Pinrui’s development is backed by 24 patents in core technologies, showcasing a dedication to continuous improvement that ultimately benefits the end-user’s profile quality.

3.2 Custom Aluminum Profiles Quality Assurance Checklist

Use this list to drill down into the technical capabilities of a potential aluminium extrusion builder.

- Question 1: What model is your Puller, and is it Full-Servo? This directly checks their capacity for stress relief. If the answer is hydraulic, proceed with caution, especially for complex designs.

- Question 2: Is your profile Stacking fully Robotic? This verifies their ability to guarantee surface quality and minimize the reliance on high labor cost for manual stacking. Automated lines using an automatic stacker offer superior protection.

- Question 3: How do you guarantee temperature uniformity during Quenching? Ask for details on their online quenching control system. Consistent temperature control is crucial for aluminium hardening and achieving the required mechanical strength.

4. Part IV Unique Perspective Debunking Three Myths about Aluminium Extrusion Company

Understanding common industry myths can save you significant time and money when sourcing custom aluminum extrusion.

4.1 Myth One The Lowest Price Makes the Best Extrusion Supplier

This is perhaps the most dangerous myth in procurement. The lowest quote often reflects the use of outdated, inefficient equipment.

- Expert View: A low-cost extrusion supplier typically operates older, often hydraulic, press lines that cannot handle the precision required for modern custom aluminum profiles. These lines fail to properly relieve residual stress, and their reliance on manual labor increases both defect rates and hidden operational costs. The initial saving is quickly negated by high failure rates in your assembly line.

- Conclusion: The total cost of ownership for custom aluminum profiles includes the cost of quality assurance and rework. An investment in a supplier using high-precision equipment offers a lower long-term cost, despite a potentially higher initial quote.

Conclusion Invest in Precision, Choose the Right Aluminium Extrusion Supplier

The quality of your custom aluminum profiles is a direct reflection of the technology used by your aluminium extrusion company. When you are searching for a reliable aluminium extrusion supplier, look past the initial price tag and scrutinize their cold-end capabilities.

The industry leaders—the true aluminium extrusion profile manufacturer specialists—invest in precision, speed, and automation. They choose advanced systems like the full-servo puller to guarantee stress-free profiles and the automatic stacker to eliminate the Finishing Line bottleneck.

Pinrui Machinery’s mission is to empower these industry-defining manufacturers. By choosing a supplier who relies on our patented, globally trusted equipment, you are choosing a partner dedicated to technical excellence.

Are you an aluminium extrusion company looking to upgrade your capabilities and secure your position as a top-tier custom aluminum extrusion provider? Or are you a buyer seeking the ultimate quality assurance? Visit our homepage today.

Contact us today to learn how Pinrui’s solutions can elevate your production standards, backed by our expertise in over 30 export countries.