Straightness issues in aluminum extrusion cost more than just scrap; they jeopardize your delivery reputation and erode profit margins through wasted energy and labor.

When finished profiles warp in the warehouse or fail to align on an assembly line, you aren’t just facing a technical defect—you are facing a commercial bottleneck. While most manufacturers focus on die adjustments, the true root of “out-of-tolerance” straightness often lies further down the production line.

Limitations of Traditional Straightness Correction Methods

Most process engineers attempt to solve bending or twisting by modifying die flow or slowing down extrusion speeds.

Correcting the die only addresses the initial metal flow at the exit point. It fails to account for the dynamic variables of temperature fluctuations and mechanical wear that occur during a full production shift. Relying on “master technicians” to manually tweak parameters creates an unstable production environment where quality varies by the hour.

Manual straightening after the fact is often a temporary mask rather than a permanent cure. For complex industrial aluminum profiles, forced stretching can introduce residual internal stresses. These stresses often release during subsequent machining or storage, causing the profile to “spring back” or warp unexpectedly.

Straightness Issues as a Syndrome of Process Misalignment

True straightness control requires a shift in perspective: stop looking at the die and start looking at the system.

Think of an aluminum extrusion line as a river system where straightness is the final flow direction. Deviations like bowing, waving, or twisting are downstream symptoms of “turbulence” caused by uncoordinated pulling, cooling, and handling stages.

Puller Misalignment: Lateral Stress on Soft Metal

If the pulling force is inconsistent or out of sync with the extrusion speed, it pulls the profile laterally while it is still in a high-temperature, “soft” state. This mechanical tug-of-war is the primary cause of long-distance bowing that die adjustments simply cannot fix.

Cooling Imbalance: The Internal Stress Tug-of-War

Uneven cooling is essentially uneven freezing of the metal structure. As the profile passes through the online quenching system, temperature deltas across the cross-section create internal contraction forces. This “thermal tug-of-war” manifests as twisting or wavy edges once the profile reaches room temperature.

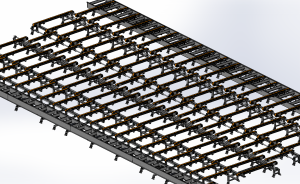

Handling Table Friction: Secondary Surface and Form Damage

Moving high-temperature profiles across an uneven or high-resistance cooling bed leads to dragging. Standard run-out tables without precision leveling can cause surface scratches and introduce subtle bends that compromise the final straightness of long-length extrusions.

The Pinrui Solution: Systemic Synchronization for Straightness

Pinrui Machinery provides a hardware-integrated approach that locks in straightness at the source through automated equipment coordination.

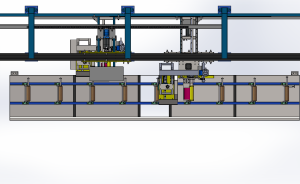

Full Servo Puller Synchronization to Eliminate Stretching

Pinrui multi-head servo pullers achieve millisecond-level synchronization with the extrusion press. By maintaining a constant, precise tension, our system ensures the profile remains perfectly neutral during the critical cooling transition, eliminating pull-induced deformation.

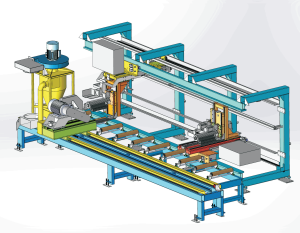

Gradient and Zonal Quenching to Neutralize Contraction Stress

Our online quenching technology allows for independent adjustment of cooling intensity across different sections of the profile. By applying “gradient cooling” tailored to varying wall thicknesses, Pinrui equipment actively offsets uneven contraction, preventing the internal stresses that lead to warping.

Integrated Straightening and Precision Sawing Loop

The final quality gate in a Pinrui line is the closed-loop between the stretcher and the finishing saw. Our systems ensure that once a profile is straightened, it is handled by automatic stackers and saws without any secondary mechanical impact, preserving the integrity of the final product.

Commercial Impact of Advanced Straightness Control

Investing in systemic straightness control isn’t just a technical upgrade; it is a strategic move to lower the Total Cost of Ownership (TCO).

Improving the yield rate directly reduces scrap costs and raw material waste. In sectors like solar frame production or precision automotive parts, a 0.5mm improvement in straightness can be the difference between a high-margin contract and a rejected batch.

Reduced reliance on manual intervention lowers labor costs and minimizes downtime. Pinrui’s automated systems allow for “set-and-forget” production, ensuring that batch #1 and batch #1000 meet the exact same straightness specifications regardless of the operator’s experience level.

Moving From Manual Tweaks to Engineering Certainty

Consistent straightness requires a transition from “artisan-based” process tuning to “hardware-based” systems engineering.

Since 2009, Pinrui has focused on providing this level of certainty to global extruders. We understand that you don’t just need a machine; you need a stable production environment that delivers high-precision profiles every single time.

Are your long-length extrusions failing the straightness test after storage? Contact Pinrui today for a technical consultation or a full audit of your handling and cooling systems to identify the root cause of your deformation issues.