Most process guides miss the real battle for margin. While extruders obsess over die chemistry or billet temperatures, the invisible losses in the runout and cooling stages often dictate whether a batch is profitable or destined for the scrap bin. It is a common industry trap to focus solely on the press while ignoring the handling damage and thermal stresses that erode the bottom line after the metal leaves the die.

Redefining Operational Excellence in the Aluminum Extrusion Process

The industry standard 11-step guide to the aluminum extrusion process serves as a useful map. However, it rarely accounts for the costly road conditions found between the milestones. Knowing the steps is not the same as mastering aluminum extrusion process control.

Operational excellence is rarely defined at the press mouth. It is won or lost during the post-extrusion handling stages. If your process map doesn’t account for thermal stress or handling-induced micro-scratches, you are navigating a minefield of unpredictable costs. Redefining your critical path by focusing on extrusion line efficiency is the only way to stabilize shrinking margins.

Discover more about optimizing your line at Pinrui Machinery

Identifying the Primary Causes of Extrusion Scrap

To fix the leaks, you must first diagnose where the quality degrades. We categorize these losses into three distinct “cost centers” that silently drain your factory’s potential.

The Cooling Quagmire and Profile Twisting Causes

Quenching is not just about making the metal cold. It is about metallurgical stability. Aluminum quenching problems often stem from uneven thermal dissipation. When one side of a profile cools faster than the other, internal stresses develop.

This imbalance leads to profile twisting causes that are nearly impossible to correct later. Uneven cooling creates “bow” and “camber,” rendering high-precision profiles useless for premium contracts. Without an advanced online quenching system, you aren’t cooling metal; you are creating mechanical instability.

Handling Damage and Extrusion Puller Alignment

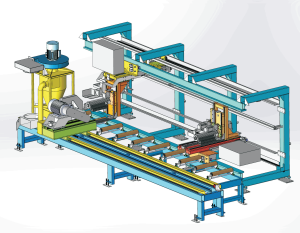

The journey from the press to the cooling bed is fraught with physical risk. Inconsistent extrusion puller alignment creates lateral tension that skews the profile. Even minor synchronicity issues between the press and the hauler lead to permanent surface defects.

Aluminum surface scratches are often dismissed as incidental. For architectural or automotive finishes, however, they represent a 100% loss of value. A poorly maintained runout table or a jerky double saw puller turns premium aluminum into expensive industrial waste.

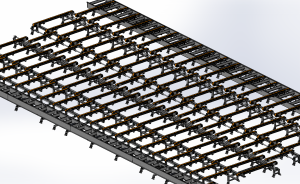

Precision Straightening and Cut to Length Tolerance

The final stages of stretching and sawing are frequently treated as brute force steps. This is a costly mistake. Aluminum stretching machine accuracy determines the final grain structure and straightness of the product.

If your cut to length tolerance is wide, you are throwing money away. Every millimeter of excess “safety margin” is unbillable material. Precision at the saw gauge and automatic stacker ensures that every gram of extruded billet contributes to your revenue.

The Pinrui Prescription for Post Extrusion Handling

Transformation requires a shift from a “correction” mindset to a “prevention” philosophy. We view each stage of the line as a data-driven control point rather than a simple mechanical task.

Stress Engineering with Online Quenching System Control

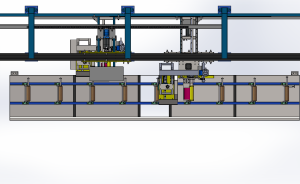

Modern online quenching system control uses gradient cooling to manage the T5 or T6 temper transition. By utilizing variable air and water flow, we prevent the differential shrinkage that causes distortion.

Instead of fighting the metal, we engineer the thermal exit. This approach ensures the profile reaches the cooling bed as straight as possible. It significantly reduces the physical burden on the stretcher and improves final product quality.

- Achieving precision online quenching control

- Technical comparison of steel versus aluminum quenching

Synchronized Motion for a Continuous Extrusion Line

A stable line requires a consistent heartbeat. Our servo controlled puller systems act as that heartbeat by maintaining constant speed and tension.

When the alternating full servo puller is perfectly synchronized with the press, the metal flows without hesitation. This stability allows the press to run at its highest rated speed. It effectively increases continuous extrusion line output without risking surface integrity or profile geometry.

Data Driven Straightness and Extrusion Cutting Tolerance

Straightening should be a measured science. Our stretcher leveler automation uses precise force feedback to ensure repeatable results every time.

By integrating translational cooling beds with high-precision finish saw systems, we achieve an extrusion cutting tolerance that meets the most stringent industrial requirements. Minimizing the “short ends” directly translates to significant aluminum scrap reduction across your entire operation.

Calculating Your Extrusion Line ROI

Investing in high-end post-process equipment is a margin growth strategy. When calculating your extrusion line ROI, look beyond the initial machine cost.

Reducing your scrap rate by just 2% can save hundreds of thousands of dollars annually. Lowering rework labor hours pads the bottom line even further. With higher precision, you can bid on lucrative automotive aluminum profile or aerospace contracts. Better consistency means fewer customer returns and higher plant uptime. Improving extrusion yield is the fastest way to increase profitability without adding more shifts or extra labor.

Your Aluminum Extrusion Consultation Action Plan

The path to higher margins starts with an honest audit of your current line. Awareness of the problem is the first step, but technical precision is the ultimate goal for any modern extruder.

Download our “Post-Extrusion Line Audit Checklist” to identify your specific leak points in under 10 minutes. This tool helps you pinpoint whether your losses are occurring at the quench, on the belt, or at the saw.

Ready for a deeper dive? Schedule a Free Data Backed Line Assessment today. Our engineers will review your extrusion line assessment and help you quantify exactly how much money is currently leaking from your production process. The difference between a standard line and a high-precision line is measured in percentage points of pure margin.