0. Introduction Procuring Aluminium Profile Must Go Beyond Price

For project managers and procurement specialists, sourcing aluminium profile is often viewed as a simple commodity transaction. However, the true cost of an aluminium profile company cannot be measured by price alone. A structurally compromised profile—one with hidden internal defects—can lead to disastrous failures in downstream manufacturing, including warping, poor fitment, and increased scrap rates.

The industry is evolving, and the best aluminium profile manufacturer partners today are those who invest heavily in process control. They recognize that quality is not added at the end, but engineered from the start, particularly in the critical “cold end” of the extrusion line.

This guide provides an authority framework. It helps you look past glossy brochures and assess potential aluminium profile suppliers based on the technical standards that guarantee zero-defect aluminium profiles—the standards set by technology leaders like Pinrui Machinery.

1. Part I Three Core Technical Dimensions for Vetting Aluminium Profile Supplier

Identifying a premium aluminium profile manufacturer requires auditing their capabilities in three fundamental areas: stress elimination, surface preservation, and material strength consistency. These dimensions define the true quality of the aluminium profiles you procure.

1.1 Zero Stress Control Full Servo Puller Technology is Key

The silent killer of precision aluminium profiles is residual stress. When profiles undergo rapid cooling during quenching treatment after extrusion, internal tensions lock into the metal structure. If these tensions are not thoroughly and uniformly relieved, the profile will inevitably warp when it is cut or machined later.

To consistently deliver zero-stress profiles, the top aluminium profile company must leverage advanced technology. This is why the full-servo puller is non-negotiable. Unlike older, less predictable hydraulic systems, the servo system provides precise, closed-loop tension control, achieving the consistent, measurable plastic deformation necessary to eradicate residual stress.

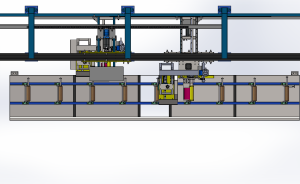

For high-volume operations, the efficiency of an alternating full servo puller is a key differentiator. It ensures continuous production without sacrificing the precision that systems like a single puller provide, setting a higher bar for the quality offered by any aspiring aluminium profile supplier.

1.2 Surface Quality Assurance The Value of Automatic Stacker Systems

Surface quality is often compromised during the transfer and stacking process. Scratches, dents, and imperfections introduced by manual labor or rudimentary handling systems are common, costly defects that are impossible to hide, particularly after anodizing. For an aluminium profile manufacturer, this represents a significant bottleneck and quality risk.

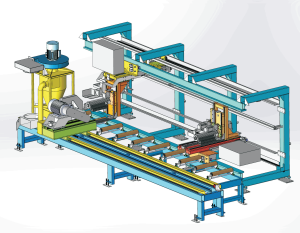

The best solution lies in complete automation of the cold end. Superior aluminium profile company partners will utilize the automatic stacker. This technology uses pre-programmed robotic arms to handle profiles gently and precisely, eliminating the potential for human error.

Integrated solutions, such as the automatic handingtable production line, guarantee that the aluminium profiles remain pristine from the cooling bed right through to the packaging stage. This mechanized approach drastically reduces reliance on high labor cost for manual stacking while ensuring a perfect surface finish for your final products.

1.3 Strength Consistency Industrial Heat Treatment Precision Control

The mechanical properties of aluminium profiles—such as yield strength and hardness (T5 or T6 temper)—are entirely dependent on controlled industrial heat treatment. Inconsistent heating or cooling leads to erratic strength across the profile, compromising structural reliability.

An elite aluminium profile manufacturer must demonstrate mastery over the online quenching process. This involves maintaining uniform cooling rates across the entire profile cross-section to ensure consistent aluminium hardening. We recommend investigating how their system achieves how to achieve precision online quenching control.

Furthermore, the quality of their ageing furnace dictates the final properties of the ageing of metals. Uniform temperature control in the furnace is essential for consistent batch quality, ensuring that every profile meets the stated mechanical specification.

2. Part II How to Evaluate and Inspect the Capacity of an Aluminium Profile Manufacturer

Before you commit to a long-term partnership, ask the hard questions. Vetting a potential aluminium profile supplier requires looking beyond their sales pitch and examining their technological backbone.

2.1 Five Key Verification Points for Aluminium Profile Suppliers

A high-performing aluminium profile company will have verifiable commitments to quality and innovation. Use these points during your factory audits:

- Technical Patents and Innovation: Does the supplier invest in leading technology? A world-class equipment provider like Pinrui holds 24 patents dedicated to refining the extrusion and finishing process. Use this number as a benchmark for your supplier’s own R&D commitment.

- International Experience and Recognition: A globally trusted aluminium profile manufacturer is a safer bet. Pinrui’s equipment is utilized by manufacturers exporting to over 30 export countries, demonstrating that the resulting profiles meet diverse, stringent international standards.

- Production Flexibility and Precision: The ability to handle varying profile sizes and complex cutting requirements efficiently points to modern equipment. Look for advanced cutting systems, such such as those utilizing the finished products saw saw gauge for automated, high-precision cutting.

2.2 Inquiry Checklist for Procurement Managers

When speaking with a prospective aluminium profile supplier, focus on the core technology, not just the capacity.

- Question 1: Is your puller system full-servo driven? This directly verifies their capacity for zero-stress profiles, which are crucial for subsequent CNC machining.

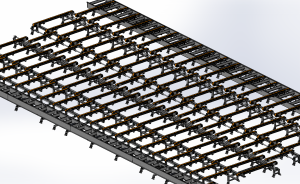

- Question 2: How have you eliminated the cold-end bottleneck? This probes their level of automation, covering everything from the translational type cooling bed production line to the automatic stacker, verifying efficiency and quality consistency.

- Question 3: How do you ensure temperature uniformity in your age hardening process? This validates their control over material strength, especially concerning the precise handling required between the quench furnace and the ageing furnace.

3. Part III Unique Perspective Debunking Two Myths about Aluminium Profile Company

To truly practice long-term SEO and procurement wisdom, we must address common industry myths that lead to poor decision-making.

3.1 Myth The Largest Aluminium Profile Supplier is Automatically the Best

Many purchasing agents mistakenly equate tonnage capacity with quality leadership. This perspective overlooks technological stagnation. Many massive aluminium profile suppliers still rely on older, less efficient, and less precise hydraulic machinery. While they offer quantity, they often struggle with the complex, high-tolerance profiles required for cutting-edge industrial and automotive applications.

A smaller, yet modern aluminium profile manufacturer equipped with the latest full-servo puller and fully integrated automation can often deliver superior quality and consistency. Focus on the technological age of their machinery, not just the size of their factory floor.

3.2 Myth Aluminium Profile Defects Can Be Fixed in Post-Processing

Another common misconception is that minor flaws—such as residual curvature or slight internal residual stress—can be corrected during later fabrication, for instance, by clamping or machining. This is fundamentally untrue. Any attempt to fix a profile with trapped stress will result in the material fighting back, leading to premature tool wear, warping during cutting, and ultimately, component failure in the field.

The defects that matter most are those that originate on the extrusion line. Therefore, choosing an aluminium profile company that uses preventative technology—like the automatic puller to actively relieve stress—is the only way to secure truly reliable material.

Conclusion Structural Reliability Starts at the Finishing Line

The decision to partner with an aluminium profile manufacturer or aluminium profile supplier is a foundational step in your own manufacturing process. By using the standards presented here, you move beyond the risks of commodity sourcing and enter into a partnership based on verified technical capability.

Pinrui Machinery is the silent partner of the world’s best aluminium profile company leaders. We design and manufacture the full-servo puller, automatic stacker, and precision cold-end systems that eliminate residual stress and surface defects, ensuring the highest global standards for the aluminium profiles you purchase.

We encourage you to use Pinrui’s technology—backed by our 24 patents and proven in 30 export countries—as the benchmark for assessing your potential suppliers. By doing so, you secure the reliability and precision your products demand.

Are you a manufacturer ready to upgrade your line to meet these global standards, or a procurement expert seeking verifiable quality data? Visit our homepage or contact us today.

Frequently Asked Questions

Q: Why is a full-servo puller better than a traditional hydraulic puller?

A: A full-servo puller provides continuous, precise tension control, which is essential for uniform stress relief in aluminium profiles. Hydraulic systems are prone to pressure fluctuations, which leave behind inconsistent residual stress that can cause the profiles to warp after cutting.

Q: How do aluminium profile suppliers minimize surface scratches?

A: Top aluminium profile suppliers minimize surface defects by implementing full automation in the cold end. This involves using systems like the automatic stacker and robotic handling tables to eliminate physical contact and friction associated with manual handling and movement.

Q: Does Pinrui sell aluminium profiles directly?

A: No. Pinrui Machinery is a leading aluminium profile manufacturer equipment provider. We supply the high-precision machinery (like the automatic puller and online quenching systems) that the world’s best aluminium profile company partners use to guarantee the quality of the profiles they sell.