Identify Your Production Bottleneck A Self-Assessment

Is your aluminum extrusion line struggling to reach its full potential? The constraint is often not the press itself, but the downstream finishing section. Manual handling, inconsistent cooling, and imprecise cutting create a drag on your overall equipment effectiveness (OEE). Before considering any equipment investment, pinpointing the exact bottleneck is critical.

Common symptoms include fluctuating profile straightness, high scrap rates from sawing, and labor-intensive stacking. These issues directly erode profit margins. Our industry analysis shows that for many extruders, over 60% of direct labor costs are tied to post-extrusion handling and correction. The first step toward a solution is a clear diagnosis.

We have developed a concise five-question checklist to help you isolate your primary constraint. This diagnostic tool focuses on observable outcomes in quenching, pulling, and cutting. You can download it to begin your assessment. For example, if profiles exhibit consistent twisting, the root cause often lies in the synchronization between the extrusion press and the puller. If warping occurs after aging, the quenching process likely lacks uniformity.

Four Strategic Paths to Downstream Automation

Once the bottleneck is identified, the next decision is selecting the right scale of automation. A one-size-fits-all approach does not work. The optimal path depends on your annual throughput, product mix, and capital readiness. We define four distinct upgrade trajectories, each with a clear purpose and return profile.

Path A targets single-point automation, ideal for shops with an output under 5,000 tons per year. This often means automating the most labor-intensive task first, such as sawing and stacking. A well-configured automatic stacker system can typically show a payback period of 10-14 months by reducing manual handling and surface damage.

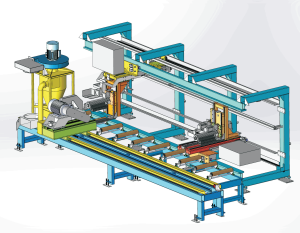

For medium-volume producers (5,000-15,000 t/year), Path B integrates entire process segments. This involves linking a precision online quenching system with an automated cooling bed and stretcher. The goal here is to tackle the core metallurgical causes of distortion, not just the symptoms. Uniform quenching minimizes residual stress, which in turn makes subsequent straightening more effective and consistent.

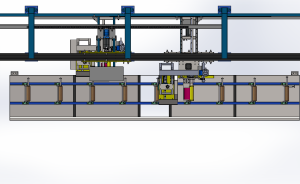

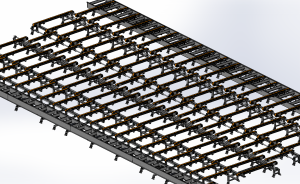

High-volume operations above 15,000 t/year should evaluate Path C: a fully continuous, hands-off finishing line. This is a synchronized system from the die to the packaged product. The major benefit is a dramatic lift in OEE, often from 65% to over 85%, by eliminating all manual transfer points and variability. One of our clients in Turkey achieved this by integrating servo pullers, a walking beam cooling bed, and an automatic stacking line.

Path D is designed for flexibility, not just volume. If you run frequent, short batches of complex profiles, your automation must adapt. This path utilizes PLC recipe control for rapid changeovers. The key is equipment like our multi-mode quenching hoods and programmable straighteners that can store settings for dozens of different profile geometries, cutting changeover time by more than 80%.

Calculating the Real ROI of Finishing Line Automation

The cost of automation is a common hurdle. However, the conversation must shift from initial price to total cost of ownership and return on investment. A proper financial model accounts for both tangible savings and intangible gains that impact your bottom line and market positioning.

Direct cost savings are the easiest to quantify. Calculate the labor hours saved per shift by replacing manual stacking or feeding. Add the value of reduced scrap. For instance, a twin-head double saw puller can optimize billet use and cut crop ends shorter, improving yield by 1-3%. For a 10,000-ton line, that can mean hundreds of tons of saved material annually.

The indirect benefits, however, often deliver greater long-term value. Superior and consistent profile straightness allows you to command a price premium or secure contracts with demanding sectors like automotive or aerospace. Furthermore, a reliable automated line provides predictable output, enabling you to accept larger, longer-term orders with confidence. It also future-proofs your operation against the growing challenge of skilled labor shortages.

We provide a detailed ROI calculator template that factors in these elements. It transforms abstract benefits into projected financial figures, giving you a clear framework for discussion with your finance team. The goal is to move from seeing automation as an expense to recognizing it as a strategic capacity investment.

Solving Core Technical Challenges in Aluminum Finishing

Understanding the engineering behind these solutions builds confidence in their effectiveness. Aluminum extrusion finishing presents unique technical hurdles that generic machinery cannot solve. The challenges are rooted in the material’s properties and the need for continuous, high-speed processing.

Achieving uniform quenching is the first major challenge. Rapid, uneven cooling locks in high thermal stress, guaranteeing downstream distortion. Traditional water baths or simple air blowers create severe temperature gradients across a profile’s cross-section. Our approach uses segmented, adjustable quenching zones. Air, mist, and water jets are independently controlled to apply a balanced cooling force on all sides of even the most complex hollow profile. This precise thermal management is the foundation for achieving consistent T5 or T6 temper properties without warping.

Maintaining stability during high-speed extrusion is the next critical phase. Any mismatch between press speed and puller traction induces twisting or surface drag lines. Hydraulic pullers with basic logic controls cannot react quickly enough. A full servo puller system operates differently. It uses real-time feedback to synchronize traction with the press output at a millisecond level. This active control maintains constant tension, ensuring the profile is guided straight onto the cooling bed without plastic deformation.

Finally, correcting the inherent residual stress requires intelligent straightening. Manually cranking a stretcher is ineffective for modern, tight-tolerance standards. Our straightening machines integrate measurement feedback. For critical applications, a laser scanning system can map the profile’s bow and twist before the stretch cycle even begins. The machine then calculates and applies the exact tensile force needed to relieve the specific stress pattern, achieving precise straightness per EN 755-9 or similar standards without over-stressing the material.

A Practical Four-Step Implementation Roadmap

The transition to automation can seem daunting. Breaking it down into a managed, phased project eliminates uncertainty and manages risk. This proven roadmap is based on our experience executing dozens of line upgrades and greenfield installations worldwide.

Step one is a comprehensive data collection and audit. Lasting two weeks, this phase involves logging key parameters: extrusion speeds for different alloys, current quenching methods and resulting temperatures, straightness measurements before and after correction, and detailed scrap tracking. This data forms the objective baseline for your project. Our engineers can provide a tailored checklist for this audit.

Step two involves conceptual design and simulation. Using the collected data, we develop a digital twin of the proposed automated line. This simulation models material flow, thermal dynamics, and cycle times to predict the new line’s performance and identify potential bottlenecks virtually before any metal is cut. You receive a report detailing the expected gains in output, yield, and quality.

Step three is staged implementation. We strongly advise against a full line shutdown for a “big bang” cutover. The most successful projects follow a phased approach, often starting with the automatic stacking cell. This delivers a quick win in labor savings and protects the finished product. Subsequent phases then integrate the stretcher, cooling bed, and finally the quenching system, minimizing production disruption.

Step four focuses on continuous optimization and support. After commissioning, we provide training and set up a key performance indicator dashboard. This allows your team to monitor the new line’s performance against targets. Our support includes remote diagnostics and the commitment that a technician will be on-site within 24 hours if an issue cannot be resolved remotely, ensuring your investment delivers sustained value.

Explore Your Custom Automation Strategy

The journey toward a more efficient and profitable extrusion line begins with a clear understanding of your unique situation. Generic advice can only go so far in a field as specialized as aluminum processing. The right automation strategy aligns precisely with your product mix, volume goals, and quality aspirations.

To move from analysis to action, we offer tailored resources. You can download our detailed Downstream Line Assessment Checklist to conduct a thorough self-audit. For a more interactive analysis, you can schedule a 30-minute consultation with one of our process engineers to review your initial findings. For companies seriously evaluating a capital project, we can generate a preliminary Line Simulation Report based on your key data, outlining projected performance improvements.

Investing in downstream automation is not merely about buying machines. It is about acquiring a systematic capability to produce higher-quality aluminum profiles with greater consistency and lower operational cost. In a competitive global market, that capability is the foundation for growth and resilience. Contact our team to start designing your solution.

Target Keywords Integration Summary:

Primary: automated aluminum extrusion finishing solutions, aluminum extrusion line bottleneck, downstream automation ROI.

Secondary: online quenching system, servo puller, automatic cooling bed, profile straightening, scrap reduction, extrusion OEE.

Related Terms: integrated finishing line, hands-off production, T6 temper consistency, residual stress control.