Are you scrolling through countless HVAC reviews trying to find the ideal system for your manufacturing operation? If your ultimate goal is to produce high-strength T6 aluminum profiles, you need to recognize one fact: the best heating and air conditioning systems on the consumer market are entirely irrelevant to industrial success.

Your equipment requirements don’t involve simply controlling the room temperature; they demand absolute metallurgical control. This process, known as T6 heat treatment, is where profiles achieve the hardness and durability that define a quality product.

The failure to select the right specialized quench furnace or full servo puller can lead to inconsistent material properties, resulting in a high scrap rate and compromised product integrity. This guide cuts through the noise of generic HVAC reviews to give you the technical clarity required to source the true best heating and cooling units for your specialized aluminum extrusion line.

I. Beyond the Thermostat: What Industrial HVAC Reviews Miss

The industrial quest for the best heating and cooling systems is fundamentally about precision and repeatability, not BTU ratings or energy labels. Every foot of your aluminum profile must achieve identical mechanical properties, a requirement that generic commercial equipment simply cannot meet.

1.1 The High-Stakes of Quenching Metal Pinrui’s Core Focus

The process of hardening aluminum is defined by two critical stages: heating the metal to a solutionizing temperature and then rapidly cooling it. This rapid cooling stage, often called quenching metal, determines the final strength of the alloy. If the cooling is uneven or too slow, the alloying elements precipitate prematurely, leading to a weak profile.

You must be certain your chosen equipment can meet the critical cooling rate required for your specific alloy. We provide in-depth resources to help you understand what is quenching and the fundamental differences in approach when comparing steel vs aluminum quenching. The quality of your quenching treatment is a direct reflection of your equipment’s precision.

1.2 Defining the Best Heating and Cooling Systems Precision Metrics

How do industry leaders objectively evaluate the best heating and cooling systems? They rely on measurable, highly technical benchmarks that go far beyond consumer-grade metrics:

- Temperature Uniformity (±3°C): The maximum allowable variation within the furnace chamber. This tight tolerance is non-negotiable for proper solid solution formation.

- Time-to-Quench: The time taken to move the profile from the furnace to the cooling medium. A delay of mere seconds can jeopardize the profile’s T6 potential.

- System Integration: The seamless synchronization between the puller, the press, and the quench unit, which is vital for effective industrial heat treatment.

II. Solving the Temperature Uniformity Crisis The Furnace Challenge

The solution heat treatment furnace is the first point of control in the T6 process. The structural strength of your finished tempered steel profile—or rather, the heat-treatable aluminum alloy—depends on the absolute consistency of this heating stage.

2.1 The Role of the Quench Furnace and Ageing Furnace

Achieving a successful T6 state requires two distinct heating steps. The quench furnace (Solution Heat Treatment Furnace) prepares the profile, while the Ageing Furnace is the final thermal step that stabilizes the strength. Both require exceptional control.

If the internal temperature of the heat-treat oven fluctuates, some sections of the load will be over-treated, and others under-treated. This leads to inconsistent final hardness. Pinrui’s commitment to precision ensures our furnaces are designed specifically to eliminate these thermal gradients, supporting the creation of age-hardened aluminum with reliable, uniform strength. Learn more about the principles of ageing of metals and the final steps of aluminium hardening.

2.2 Patented Airflow Guaranteed Uniformity for Annealing Aluminium

How does Pinrui guarantee temperature consistency across a large furnace volume? We rely on advanced engineering, backed by 24 specialized patents in areas like this.

- Optimized Air Circulation: Our designs utilize powerful, multi-zone airflow systems to rapidly and uniformly distribute heat, minimizing hot spots and ensuring successful annealing aluminium conditions.

- Intelligent Burner Control: We employ high-efficiency burner technology coupled with sophisticated PLC systems to maintain constant thermal output. This modulation ensures the tight temperature tolerance needed while optimizing the crucial furnace flame efficiency. Our detailed technical resources can guide you on how to aluminium hardening successfully. Additionally, understanding the differences between annealing vs tempering is crucial for metallurgical success.

III. The Second of Precision Pinrui’s Full Servo Puller and Quenching

If the furnace creates the strength potential, the cooling system and the handling equipment lock it in. This is the moment when the profiles are most vulnerable to distortion and strength loss.

3.1 The Critical Speed of Online Quenching

The fastest way to achieve the Critical Cooling Rate is by implementing immediate, powerful Online Quenching. This technology applies the cooling medium the moment the profile exits the press, reducing the time profiles spend in the “danger zone” where unwanted precipitation can occur.

Pinrui’s dedicated Online Quenching systems use highly efficient spray technology (water or mist) to deliver rapid, uniform cooling. This is the key component in how to achieve precision online quenching control and maximize the material’s final T6 properties.

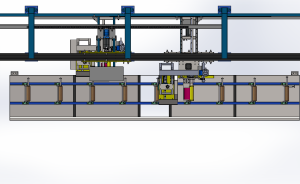

3.2 Automated Tension The Twin-Head Double-Saw Puller Advantage

A superior Online Quenching unit is ineffective if the profile is mishandled. The puller must guide the fragile, hot aluminum at precisely the right tension and speed. This is why the choice of full servo puller technology is paramount.

Pinrui’s range of intelligent pullers, including the twin-head double-saw puller, the versatile alternating full servo puller, and the economical single puller, ensure zero-slip and perfectly controlled tension.

- Zero-Slip Operation: The alternating full servo puller maintains constant, precise tension, preventing the profile from buckling or twisting as it is rapidly cooled. This directly impacts dimensional stability.

- Speed Synchronization: The puller speed is matched precisely to the press, a feature enhanced in the advanced models for continuous extrusion flow.

- Damage Minimization: The advanced design, including the specific features of our twin-head double-saw puller features, ensures the profile surface remains pristine throughout the demanding quench process.

We offer various models, from the simplified automatic puller to the advanced alternating full servo puller, tailored to your production volume.

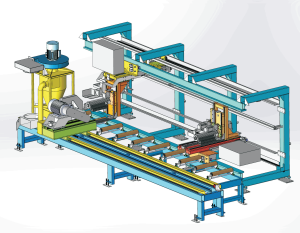

IV. From Quench to Stack Mastering Backend Consistency

The T6 process doesn’t end at the quench unit. The entire backend—from the cooling bed to the final stacking—must operate with the same high level of precision to preserve the profile’s straightness and quality.

4.1 Maintaining Straightness on the Cooling Bed

After the quench, the profiles are still hot and malleable. The design of the cooling bed and handling equipment is critical to prevent warping.

Pinrui offers specialized solutions for this crucial stage:

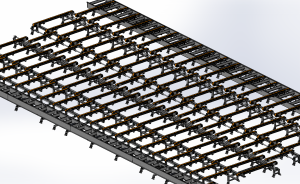

- Translational Cooling Beds: The translational type cooling bed production line handles profiles gently, minimizing friction and preventing scratches or bending during transport.

- Belt-Type Efficiency: The belt type cold bed production line provides a smooth, controlled transition, ensuring profiles cool evenly and maintain their straightness. This seamless movement is guaranteed by our automatic handingtable production line.

4.2 Finishing with Zero Tolerance Saw and Stacker Integration

The final steps involve cutting to length and preparing for delivery. This seemingly simple stage also requires specialized equipment to maintain the profile’s quality.

Our finished products saw saw gauge systems, combined with the finish saw and saw gauge system machine, provide high-precision cutting. Once cut, the profiles are handled gently by the automatic stacker, which prepares them for the Ageing Furnace or storage with minimal risk of damage or deformation. This continuous, careful process is key to delivering a high-quality product ready for use as tempered steel alternatives.

V. Pinrui’s Proven Expertise: 24 Patents, 30 Countries

When searching for the best air conditioning and heating solution for your plant, you need a specialist, not a generalist. Pinrui Machinery, founded in 2009 in China’s renowned aluminum production base, is exactly that specialist.

Our commitment to innovation is clear: we hold 24 patents focusing exclusively on optimizing the aluminum extrusion line. This expertise is trusted globally, as we provide equipment and support to customers in over 30 export countries. We don’t just sell machinery; we deliver patented solutions that solve the real-world problems of T6 production.

5.1 A Specialized Partner Beyond Generic HVAC

Unlike suppliers offering generic industrial equipment, Pinrui focuses on the specific thermal and mechanical stresses of T6 aluminum. Our systems are integrated to prevent the cascading failures that happen when a press, puller, and quench unit don’t synchronize perfectly. This specialized knowledge is what separates a reliable production line from a liability.

VI. Redefine Your Production Quality with Pinrui

The search for the best heating and cooling units for your industrial needs stops here. You require specialized, patented technology that guarantees metallurgical precision and operational reliability, supported by a proven global partner.

We invite you to stop wasting time on generic HVAC reviews and start focusing on the factors that truly impact your bottom line—profile quality, T6 strength, and operational efficiency.

Ready to move beyond generic HVAC solutions and achieve guaranteed T6 quality?

We understand that equipment procurement is a high-cost, high-stakes decision. That’s why we offer a low-barrier opportunity for collaboration. Click the link below to schedule a Free Technical Line Assessment with one of our specialized engineers. We will analyze your current T6 bottlenecks and show you the proven advantage our patented puller and online quenching systems can provide.

Schedule Your Free Technical Line Assessment Today

Visit our homepage to explore our full range of innovative aluminum processing solutions.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between Pinrui’s equipment and a standard industrial heating and air conditioning unit?

A: Standard units manage ambient climate. Pinrui’s equipment manages the metallurgical process of T6 heat treatment. Our full servo puller and Online Quenching units focus on high-speed, high-precision movement and cooling to lock in the metal’s strength, a function that standard best heating and air conditioning units cannot perform.

Q2: How do Pinrui’s 24 patents benefit my T6 production line?

A: Our 24 patents represent continuous innovation focused on optimizing speed, minimizing distortion, and improving material quality during the aluminum processing line. These patented technologies, especially in areas like the twin-head double-saw puller and specialized Ageing Furnace design, translate directly into higher profile quality and lower scrap rates for your operation.

Q3: Does Pinrui offer support in regions outside of China?

A: Yes. Pinrui is an international supplier, proudly exporting equipment and providing support to over 30 export countries. Our global experience ensures we understand and comply with various international standards and logistics requirements.

Q4: How does the aging process fit into the overall heating and cooling system?

A: The Ageing Furnace, often considered the final heating stage, is where the profile’s strength is finalized. After the rapid cooling (quenching treatment) phase, the profile requires controlled reheating for a specific duration (ageing of metals). The furnace must have excellent temperature uniformity to ensure consistent final hardness across the entire batch.

Q5: Where can I see a complete list of your extrusion line equipment?

A: You can view our complete range of specialized equipment, including various puller types, cold beds, and handling systems, by visiting our main website.