0. Introduction Aluminium Extrusion Brackets The Core Role in Structural Assemblies

In modern automation, construction, and photovoltaic systems, the structural integrity of the entire frame often hinges on small, critical components: aluminium extrusion brackets. These components, which connect the main profiles, are the load-bearing joints in any aluminum structure built by an aluminum extrusion builder.

The quality of these aluminum extrusion brackets dictates the reliability, rigidity, and lifespan of the entire assembly. A slight deviation in fit or dimension can lead to cumulative tolerance errors, stress concentration, and premature structural failure.

This guide moves beyond simple material discussions. We will provide a deep, technical look at why the quality of an extruded aluminum bracket is not determined by the bracket manufacturer alone, but by the cold-end technology used by the upstream aluminium extrusion profile manufacturer who supplies the raw material.

1. Part I The Root of Bracket Quality Stress and Precision Challenges

For an aluminium extrusion bracket to perform its job flawlessly, its raw profile material must be fundamentally sound—specifically, free of internal stress and perfectly straight.

1.1 The Stress Trap in Aluminium Extrusion Brackets Manufacturing

Residual stress is the silent enemy of high-precision components. All aluminum profiles, after exiting the press, undergo rapid cooling—a process known as quenching treatment. This change in temperature inevitably locks in internal residual stress, particularly in complex shapes.

When this stressed profile is then cut, punched, or milled to create an aluminium extrusion bracket, the material is mechanically relieved. This stress release causes a subtle but fatal deformation, leading to warping or twisting of the bracket. This compromised fit results in reduced joint stiffness, undermining the strength of the entire framework.

To manufacture truly high-performance extruded aluminum brackets, the only viable solution is to use profiles that have undergone precise stretching immediately after online quenching, actively pulling the internal stress out of the material.

1.2 Dimensional Tolerance Transfer The Fitment Challenge of Extruded Aluminum Brackets

A common pitfall in the supply chain is the compounding of tolerance errors. The tolerance of the raw aluminum extrusion profile is directly transferred to the final extruded aluminum brackets.

If the initial profile has excessive deviation in flatness or parallelism, the subsequent machining steps—like drilling mounting holes—cannot correct the fault. This leads to cumulative tolerance risk. For users, this means the mounting holes on the aluminum extrusion brackets may not align perfectly with the T-slots in the main profile, complicating or even preventing proper installation.

A dependable aluminium extrusion profile manufacturer must therefore master the control of straightness, twist, and precise cross-sectional dimensions to deliver material worthy of becoming precision aluminium extrusion brackets.

2. Part II How to Ensure Raw Material Quality for Brackets Pinrui’s Finishing Line Standards

The difference between a mediocre aluminum extrusion brackets supplier and an excellent one is often the equipment they rely on. Pinrui specializes in the advanced technology that eliminates the fundamental causes of bracket failure.

2.1 Puller Technology The Only Guarantee for Zero-Stress Aluminum Profiles

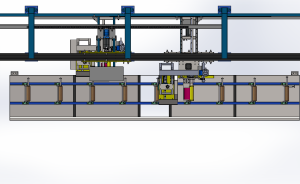

The core mechanism for stress elimination in the aluminum industry is the puller. The true guarantee for high-quality, zero-stress raw material for extruded aluminum brackets is the full-servo puller.

Unlike older hydraulic pullers, the servo system provides continuous, closed-loop tension control, allowing for precise, controlled plastic deformation that eradicates residual stress from the profile. This is crucial for applications that demand high structural reliability. For high-volume production, the alternating full servo puller ensures this quality is achieved efficiently and consistently.

Whether utilizing a single puller or a twin head system, the servo technology defines the quality standard. Aluminium extrusion profile manufacturers who invest in this level of technology are making a clear commitment to providing the best raw material for high-tolerance components like aluminium extrusion brackets.

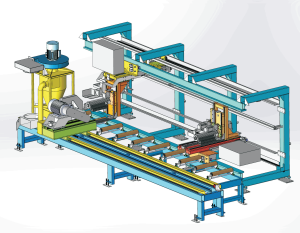

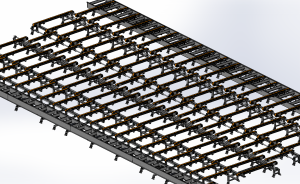

2.2 Automated Handling Protecting the Future Surface of Aluminium Extrusion Brackets

The surface finish of an extruded aluminum bracket must be pristine for optimal performance, especially prior to coating or anodizing. Scratches or dents introduced during manual handling are common, costly defects.

Automation, specifically the automatic stacker, solves this chronic problem. A fully integrated and automated production line, utilizing systems like the automatic handingtable production line and the automatic stacker, handles the profiles gently and consistently.

This mechanized process completely eliminates the potential for human error and reduces the reliance on high labor cost for manual stacking. Pinrui’s integrated solutions ensure the profile is scratch-free all the way through the finished products saw saw gauge and into the stack, guaranteeing a perfect surface finish for your final aluminum extrusion brackets.

3. Part III Practical Guide Five Steps to Procure Extruded Aluminum Brackets

For procurement specialists and aluminum extrusion builders, a rigorous vetting process is essential to secure reliable extruded aluminum brackets.

3.1 Evaluation Process for Extrusion Supplier of Brackets

When assessing a potential extrusion supplier for brackets, your focus must extend beyond their CNC capabilities to their material sourcing.

- Step 1: Trace the Raw Material Origin: Demand proof that the supplier’s raw aluminum extrusion profiles are sourced from an aluminium extrusion profile manufacturer utilizing full-servo puller technology for stress elimination.

- Step 2: Inspect Surface Flatness: Test sample aluminium extrusion brackets for perfect coplanarity on the mounting surfaces. Any inconsistency suggests poorly relieved residual stress in the source material.

- Step 3: Verify Strength Reports: Request verified torque and shear testing data for the aluminum extrusion brackets. The ultimate strength is heavily reliant on uniform material properties achieved through precise industrial heat treatment.

- Step 4: Confirm Processing Precision: Ensure the bracket supplier uses high-precision sawing and punching tools that prevent burrs, ensuring the integrity of the final product.

- Step 5: Assess Global Reliability: Partner with an extrusion supplier whose materials are globally recognized. Pinrui’s equipment is trusted by manufacturers exporting to over 30 export countries, a testament to the quality and consistency of the resulting profiles.

4. Part IV Unique Perspective The Future and Challenges of Aluminum Extrusion Brackets

As design complexity increases, the demands on the aluminum extrusion brackets will only become more challenging.

4.1 Myth Bracket Strength Only Depends on Thickness

Many assume that simply increasing the gauge or thickness of the aluminium extrusion brackets will solve all strength problems. This is a common and costly misconception.

The structural integrity of extruded aluminum brackets is governed by its material properties. A thicker bracket made from a highly-stressed profile will be weaker and more prone to failure than a thinner, zero-stress component. True strength comes from the correct internal structure, achieved through uniform quenching treatment and precise mechanical stretching.

This commitment to technical superiority is why leading equipment manufacturers like Pinrui hold numerous patents—we have 24 patents dedicated to refining the extrusion supplier production process, guaranteeing a better foundation for every aluminum extrusion bracket built.

Conclusion Structural Reliability Starts at the Finishing Line

The procurement decision for high-performance extruded aluminum brackets must be a technical one. The reliability of your final assembly hinges on a material that is dimensionally perfect and internally stress-free.

Pinrui Machinery is dedicated to supplying the world’s best aluminium extrusion profile manufacturers with the technology to achieve these stringent standards. Our full-servo puller eradicates residual stress, and our automatic stacker protects surface quality, directly enabling the production of the zero-defect raw profiles needed for your aluminium extrusion brackets.

By choosing a bracket extrusion supplier who utilizes Pinrui-grade equipment, you are securing a competitive edge built on verifiable quality. Don’t settle for less when structural integrity is on the line.

Are you ready to ensure your aluminum extrusion brackets meet the highest global standards? Contact us today to discuss how Pinrui’s advanced finishing lines can support your manufacturing or procurement requirements.

Visit our homepage for more information on our advanced solutions.

Frequently Asked Questions

Q: What is the biggest quality risk when purchasing extruded aluminum brackets?

A: The biggest risk is using brackets made from raw profiles containing high residual stress. This stress is often hidden but causes the aluminum extrusion brackets to warp after being cut, leading to poor fitment and compromised structural integrity in your final assembly.

Q: How can I tell if an aluminium extrusion profile manufacturer is high quality?

A: The most reliable indicator is their cold-end equipment. Check if they use a full-servo puller for stress relief and an automatic stacker for precise, damage-free profile handling. These technologies eliminate the most common causes of profile defects.

Q: Why is automated handling important for aluminum extrusion brackets?

A: Automated handling, particularly with an automatic stacker, eliminates the scratches and dents caused by manual labor. For an extruded aluminum bracket that requires coating or anodizing, a flawless surface is essential for the final finish.