When your high-capacity aluminum extrusion line suffers a failure—be it a critical Ageing Furnace or a precision online quenching unit—the seconds count. Your first, desperate search is often for affordable furnace repair near me or a local furnace repairman. This immediate, B2C mindset is understandable, yet it is precisely where most industrial operators make their most expensive mistake.

Why? Because your equipment is not a home boiler. It is a highly specialized piece of metal processing machinery. A general furnace repair person offers a quick fix that only addresses the symptom, not the root cause. This leaves you vulnerable to repeated, catastrophic downtime and devastating quality loss, especially when trying to maintain strict T6 standards for age-hardened aluminum.

This guide, written by furnace experts in the aluminum equipment industry, shows you how Pinrui Machinery, backed by 24 patents and a presence in over 30 export countries, shifts your strategy from risky reactive fixes to guaranteed process reliability.

I. The Critical Disconnect Why ‘Inexpensive Furnace Repair’ Destroys Profit

The allure of inexpensive furnace repair is powerful. However, for a production facility, this choice is always a false economy. The core problem lies in the difference between residential heating (best heating and air conditioning units) and precision industrial industrial heat treatment.

The High Cost of a Generic Furnace Service Repair

When a general gas furnace service company answers your call for a furnace repair near me free estimate, they lack the specialized knowledge required for non-ferrous metallurgy. Their expertise stops at restoring basic function, ignoring the complex thermal dynamics crucial for aluminum quality.

A simple, uncalibrated furnace service repair on your heat treat oven can lead to:

- Non-Uniformity: Failure to achieve the required thermal uniformity (often ±3°C) within the Ageing Furnace (ageing of metals) results in inconsistent material properties across the profile batch.

- Scrap Rate Spikes: Profiles fail certification because the necessary aluminium hardening or tempering process (tempered steel) was compromised. For more on this, see how to aluminium hardening.

- Repeated Failure: Without addressing underlying control system drift or airflow balance, you are guaranteed to need another emergency heating furnace repair service call soon.

The financial damage from downtime and scrap profiles far outweighs the initial savings from choosing the cheapest furnace fixers near me. Your priority must be process integrity, not low hourly labor rates.

II. Pinrui’s Process Assurance How We Solve Your Equipment Problems

Pinrui Machinery does not offer generic furnace repairs; we provide complete process solutions designed specifically for high-capacity aluminum extrusion lines. Our specialization ensures that every component—from the Quench Furnace to the finished products saw saw gauge—operates in perfect synergy.

A. Guaranteeing Thermal Precision The Quench and Ageing Systems

The quality of your T6 aluminum lives and dies by the precision of your industrial heat treatment. When you need service on your Drop Bottom Furnace or Ageing Furnace, you need a specialist who understands the thermal chain.

Our service philosophy focuses on system calibration:

- Online Quenching Integrity: We ensure your online quenching system achieves the required cooling rate immediately after extrusion. This rapid cooling is vital to lock in the proper microstructure. Understanding how to achieve precision online quenching control is a key differentiator in our service. See also what is quenching and the differences between steel vs aluminum quenching.

- Temperature Uniformity Surveys (TUS): Our technicians perform rigorous TUS and thermal mapping, calibrating every zone of the heat treat oven to eliminate cold spots that compromise material quality. This is fundamental to proper quenching treatment and quenching metal.

- System Upgrades: If your existing furnace is inefficient, we can evaluate a targeted furnace replacement service for a high-efficiency model, ensuring better thermal stability and reducing the total energy cost for your industrial heat treatment.

B. Eliminating Profile Defects The Role of Intelligent Pullers

Heat treatment is only half the battle. If the profile is twisted, scratched, or stretched as it leaves the press, the T6 properties will be compromised. This is why our intelligent pullers are engineered with 24 patents dedicated to zero-defect handling.

When you invest in Pinrui Machinery pullers, you eliminate the most common post-extrusion defects:

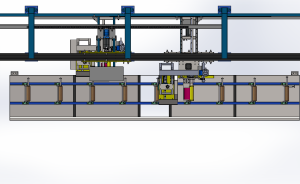

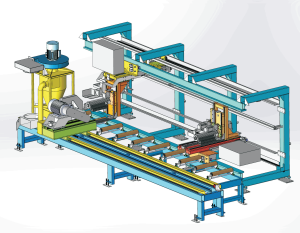

- Twin-Head Double-Saw Puller: Designed for continuous, high-speed operation, its advanced twin-head double-saw puller features ensure smooth, non-stop pulling, preventing uneven stretching and maintaining profile straightness.

- Full Servo Control: Our full-servo puller, including the single puller and the high-performance alternating full servo puller, uses precise motor control to synchronize speed with the press, preventing slippage and surface damage. Even our standard automatic puller systems are engineered for superior speed regulation.

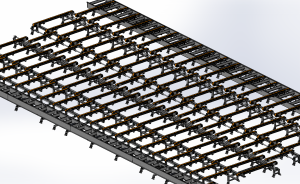

- Cooling Bed Integration: The single puller or automatic puller works seamlessly with the translational-type cooling bed production line to gently transport hot profiles without introducing defects before they reach the final cut and stacking systems (automatic stacker). You can also utilize our belt-type cold bed production line.

C. Seamless Downstream Automation

The final step—cutting and stacking—must be precise to avoid damaging expensive, age-hardened aluminum profiles. Our systems ensure accuracy:

- The automatic handingtable production line moves profiles efficiently and safely from the cooling zone.

- Our finish saw and saw gauge system machine guarantees precise, repeatable cut lengths, working hand-in-hand with the finished products saw saw gauge for minimal material waste.

III. Proactive Strategy Moving Beyond the ‘Who to Call for Furnace Repair’ Mindset

The goal of a world-class manufacturing operation is to never need to ask who to call for furnace repair. This requires adopting a proactive, predictive service strategy that focuses on total system management.

The Power of Local Furnace Maintenance and Predictive Diagnostics

Our specialized local furnace maintenance service is not about fixing what is broken; it is about preventing the break in the first place. This strategy significantly extends the operational lifespan of your ageing furnace and quench furnace systems.

Key pillars of our preventative service:

- System Audits: Regular calibration checks of all thermal components, including an analysis of the furnace flame to ensure optimal combustion efficiency and energy consumption.

- Puller Calibration: Verifying the alignment and synchronization of the full-servo puller and twin-head double-saw puller to maintain zero-defect profile handling.

- Process Consultation: Reviewing your annealing vs tempering and quenching treatment protocols to ensure they align with the capabilities of your equipment and the desired final properties of the tempered steel. We help you understand the core differences between processes like annealing aluminium and aluminium hardening.

Strategic Furnace Replacement Service Evaluation

If your equipment is causing chronic issues—resulting in you constantly searching for places that fix furnaces—it is time to analyze the Return on Investment (ROI) of a furnace replacement service.

A new, custom-engineered Pinrui Machinery Ageing Furnace or Drop Bottom Furnace offers superior insulation, modern control systems, and dramatically improved energy efficiency, leading to lower operating costs and guaranteed T6 quality. We leverage our knowledge gained from serving clients in over 30 export countries to recommend the optimal equipment choice for your regional needs.

IV. Your Next Step Stop Searching, Start Solving

You now understand that the solution to your equipment instability is not a general handyman offering furnace repair near me, but a specialized industrial equipment partner like Pinrui Machinery.

Our commitment, validated by 24 patents, is to eliminate unscheduled downtime and ensure you consistently produce high-quality, T6 certified profiles using our integrated equipment—from the alternating full servo puller to the precise finish saw and saw gauge system machine systems.

It’s time to stop the costly cycle of temporary fixes.

We invite you to experience the Pinrui difference with a high-value, low-risk offer:

Schedule Your Free 15-Minute Remote System Health Check

Instead of a generic sales call, schedule a complimentary consultation with one of our specialized engineers. We will analyze your current equipment, diagnose potential failure points in your thermal systems (Ageing Furnace, Drop Bottom Furnace), and provide actionable, specific advice to immediately improve your line’s stability and output quality.

Take Control of Your Downtime Today: Click here to schedule your free system health check and connect with our global team: Contact us.