If you are manufacturing high-strength aluminum profiles, you know the daily challenge: Inconsistent T6 temper is eating into your profit. That final, critical aluminium heat treatment phase often dictates whether tons of expensive material become a certified, high-value product or scrap.

The difference between a 70% and a 95% T6 yield is the difference between struggling and dominating your market. Achieving that consistency demands equipment that goes beyond standard functionality. It requires systems backed by deep expertise, like Pinrui Machinery, founded in 2009 and relied upon across 30 export countries, holding 24 patents dedicated to perfecting this process.

This article details how world-class heat treating aluminum is achieved, focusing on the equipment-based solutions that eliminate the thermal bottlenecks causing your highest costs.

I. The Profit Killers: Why Standard Quenching Fails High-Strength Alloys

The drive for lightweight structural components—from EV battery trays to complex aerospace profiles—has made the T6 temper a minimum requirement. Yet, many extrusion lines still struggle to hit T6 consistently.

The True Cost of Inconsistent Quenching

The primary culprit is non-uniform or delayed cooling—the make-or-break moment known as quenching treatment. If the profile cools too slowly, hardening elements prematurely precipitate out of the solution, preventing the final age-hardened aluminum state.

This thermal failure leads directly to three major operational headaches:

- Massive Scrap Rates: Profiles that fail the T6 strength test are immediately devalued, often resulting in significant material loss.

- Warping and Stress: Poor cooling generates high internal stress, leading to excessive profile warpage that requires lengthy and costly straightening.

- Inconsistent Quality: Varied material properties lead to customer rejections, damaging your reputation in quality-sensitive sectors.

The solution is moving from general cooling to micro-controlled, instant online quenching management.

II. Mastering the T6 Aluminum Heat Treatment Process: SHT to Aging

The T6 temper is the pinnacle of aluminum strength, and its achievement relies on executing three sequential steps perfectly.

Step 1 Solid Solution Treatment (SHT) The Foundation of Strength

Before the actual cooling begins, the profile must be prepared in the SHT phase. This involves heating the material to a precise, high temperature in a dedicated quench furnace to ensure all alloying elements are fully dissolved into the aluminum matrix.

- Precision Requirement: Uniform temperature is non-negotiable. Pinrui’s furnace designs ensure minimal temperature deviation (e.g., ±3°C), guaranteeing a homogenous starting point for the aluminum heat treatment process.

- Why it Matters: Any undissolved particles at this stage will become weak points, limiting the maximum possible T6 strength, regardless of how well the profile is aged later.

Step 2 Instantaneous Quenching Control

This is the most time-critical step. The material must be cooled from SHT temperature to below the Critical Cooling Rate within seconds. This rapid drop “freezes” the hardening elements in a supersaturated state.

The key to success here is not just speed, but uniformity.

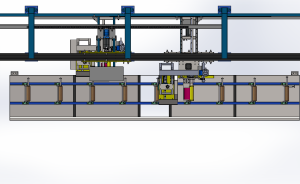

How to achieve precision online quenching control? It demands immediate, full-coverage cooling, often utilizing multi-zone water, air, or mist sprays. Our online quenching systems are designed to provide this coverage the moment the profile exits the press, crucial for alloys that require an ultra-fast quench.

Step 3 Controlled Aging: Finalizing the Aluminium Hardening

After the profile is successfully quenched (a process similar in principle to quenching metal), it is artificially aged in an ageing furnace. This involves heating the profiles to a lower temperature for a specific duration, allowing those frozen elements to precipitate uniformly and strengthen the alloy.

- Furnace Technology: Pinrui’s specialized drop bottom furnace and horizontal ageing furnace options feature superior thermal insulation and circulation systems. This guarantees the consistent environment needed for perfect ageing of metals, ensuring every profile meets the target mechanical specification.

III. Pinrui’s Solution: Tackling the Biggest Challenge – Thermal Stress and Warpage

The thermal shock created during the quenching treatment is what causes profiles to bend and twist. Warped profiles not only require extensive post-processing but can also be weakened due to non-uniform stress relief.

The pain point: How do you pull a profile rapidly without introducing uncontrollable stress and deformation?

Pinrui’s Patented Puller Technology: The Proactive Warpage Solution

The secret lies in applying a precise, calculated counter-tension during the cooling phase. Our patented full servo puller systems are designed for this exact task.

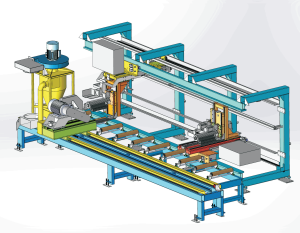

- Precision Tension Management: The full servo puller uses high-speed, dynamic servo motors to continuously adjust the pulling force as the profile cools on the translational type cooling bed production line. This proactive tension application compensates for the shrinking forces of rapid cooling, significantly minimizing warpage before it occurs.

- Efficiency Options: For high-output lines, the alternating full servo puller ensures continuous operation without the time loss associated with single-head systems. For simpler lines, the efficient automatic puller or single puller provides essential tension control.

- Result: By mastering this dynamic control, manufacturers can virtually eliminate the need for manual, damaging straightening, drastically lowering scrap and post-processing labor costs. Check out the key twin head double saw puller features that enable this precision.

IV. From Press to Pallet: Integrated Line Automation for T6 Quality

Achieving high-yield T6 output is not just about the furnace; it’s about the seamless, damage-free movement of the profile throughout the entire production cycle.

Eliminating Damage in the Cold Bed and Handling Stages

A significant amount of profile damage occurs after the quench, often during transfer. Even minor scratches or dents can cause structural failure or aesthetic rejection, especially for architectural or exposed components.

Pinrui’s integrated line components ensure profiles are protected every step of the way:

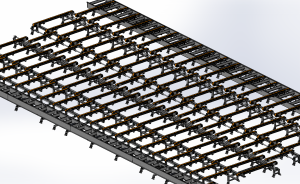

- Gentle Transfer: The belt type cold bed production line provides a smooth, non-abrasive surface for profiles, minimizing drag and surface damage during cooling and transport.

- Automated Logistics: The automatic handingtable production line and the automatic stacker gently organize and package finished profiles, eliminating the manual handling risks that lead to costly scrap.

Precision Cutting: Finalizing the Profile

Once the aluminium heat treatment process is complete, precise cutting and final sizing are mandatory.

- Accuracy Guaranteed: Our finished products saw saw gauge systems, including the advanced finish saw and saw gauge system machine, use high-precision measurement and cutting technology. This ensures every piece meets final dimensional specifications, guaranteeing that the high-quality age-hardened aluminum profile is accurately delivered to the client.

V. Advanced Technical Insights: The Metallurgy of Consistent Strength

Understanding the metallurgy helps you optimize your process parameters.

Quenching: More Than Just Cooling

While often compared to the steel vs aluminum quenching difference, aluminum’s requirement is unique. The cooling rate must be fast enough to lock the elements in solution, but not so fast that it causes excessive stress. This is why multi-zone online quenching is critical.

- Annealing vs. Tempering: It is important not to confuse this process with annealing vs tempering. Annealing aluminium involves softening the material, while tempering (like T6) is the strengthening process. Even the discussion of tempered steel involves a different underlying metallurgical reaction than aluminium hardening.

The Future of Industrial Heat Treatment

The trend is clear: full servo puller control integrated with IIoT data from the quench furnace and online quenching nozzles. This provides a closed-loop system where machine learning algorithms automatically adjust parameters in real-time to maintain the highest T6 yield regardless of minor fluctuations in alloy or die temperature.

Conclusion: Stop Guessing. Start Guaranteeing T6 Quality.

Inconsistent quality and high scrap rates are not unavoidable industry costs—they are symptoms of outdated or inadequate aluminium heat treatment equipment. Pinrui Machinery’s integrated, patented solutions are specifically engineered to eliminate these profit killers. Our technology ensures every profile achieves maximum age-hardened aluminum strength, backed by systems proven across 30 export countries.

From the instant control of the online quenching system to the proactive warpage prevention of the twin head double saw puller, we deliver the precision required for tomorrow’s structural components.

Are you ready to stop managing scrap and start guaranteeing T6 quality?

We invite you to take the low-threshold first step: Request a Free Line Audit. Let our experts assess your current extrusion and heat treating aluminum setup to identify high-cost bottlenecks and demonstrate how Pinrui’s 24 patents can significantly increase your consistent T6 yield. Visit Pinrui Machinery or contact us today to schedule your consultation.