In aluminum extrusion production, achieving consistent material properties is critical. One of the most common challenges manufacturers face is quenching inconsistency, which often leads to profiles with distortion, twisting, uneven hardness, and poor surface quality. Precise control of the cooling process immediately after extrusion is the key to eliminating these defects.

Understanding the Root Cause: The Need for Precise Cooling Control

These issues typically stem from an inability to accurately manage the cooling rate. Different aluminum alloys and profile thicknesses require specific quenching intensities—from gentle air cooling to aggressive water spraying. An improper or uneven cooling process fails to achieve the desired metallurgical properties, resulting in scrap and rework.

The PinRui Solution: Precision Engineering for Uniform Quenching

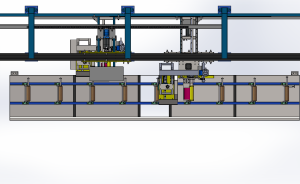

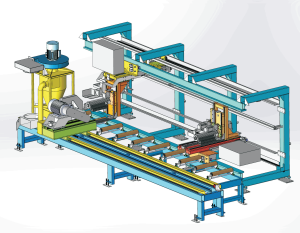

Addressing this requires a system capable of precision and flexibility. PinRui’s Online Quenching System is engineered to provide exact control over the quenching process.

Multi-Mode Cooling Flexibility

Its multi-mode cooling capability supports powerful air cooling, air-mist mixture, and high-pressure water jet cooling. This allows operators to select the perfect quenching intensity for specific alloys like 6061 or 6063, ensuring optimal mechanical properties without causing distortion.

Independent Top and Bottom Control

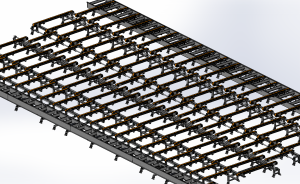

Furthermore, the system’s modular upper and lower structure allows for independent adjustment of cooling parameters on the top and bottom of the profile. This compensates for thermal gradients, guaranteeing uniform cooling across the entire profile and significantly enhancing dimensional stability.

Built for Reliability and Consistent Output

To ensure lasting performance and process repeatability, the system is built with corrosion-resistant Grade 304 stainless steel components and managed by an automated PLC control system. The PLC stores recipes for different products, drastically reducing setup time and minimizing human error, which leads to consistent, high-quality output batch after batch.

Conclusion: Enhance Your Production Line with Precision Quenching

By mastering the quenching process, manufacturers can directly improve yield, enhance product quality, and boost overall line efficiency. If quenching inconsistency is impacting your production, exploring a tailored solution is the next step.

Contact PinRui’s engineering team today to discuss how our quenching systems can be integrated into your operation to solve your specific challenges.