Surface aesthetics are only the visible tip of the iceberg in profile manufacturing. True quality is forged in the invisible transition from the die exit to the cooling bed. For high-end industrial sectors, the challenge lies in maintaining structural integrity while pushing the limits of geometry.

Why Curved Extruded Aluminum Demands Dynamic Stress Control

Traditional stretching methods often fail when dealing with complex, non-linear geometries. When producing curved extruded aluminum, the internal grain structure undergoes asymmetric tension that can lead to microscopic fracturing. Standard pullers lack the sensitivity to compensate for these localized stress concentrations.

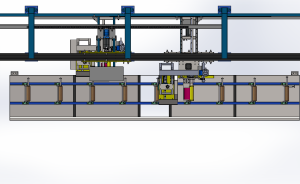

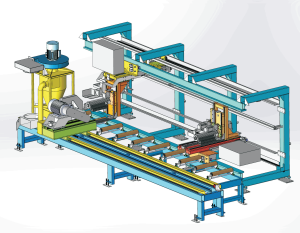

Pinrui Machinery addresses this through synchronized multi-axis control. Our alternating full servo pullers manage the profile exit with millisecond-level precision. By neutralizing the “spring-back” effect during the extrusion phase, we ensure that curved aluminum extrusions maintain their design radius without requiring secondary manual correction.

The Quenching Paradox: Speed Versus Structural Stability

Rapid cooling is essential for T6 tempering, yet it is the primary architect of profile distortion. If the temperature drop is uneven across a multi-hollow section, the resulting thermal shock creates permanent warping. This is the “Quenching Paradox” that haunts many extrusion plants.

Uniformity is the only antidote to distortion. Pinrui’s online quenching systems utilize a proprietary air-water mist configuration. By adjusting the spray density based on the specific wall thickness of the aluminium extrusion parts, the system achieves a balanced cooling gradient. This technological leap is detailed in our guide on achieving precision online quenching control.

Eliminating Information Silos Between Pullers and Cooling Beds

Most production bottlenecks occur at the “handshake” between the puller and the handling table. If the handling system cannot match the instantaneous speed of the extrusion press, the profile undergoes unwanted “necking” or stretching. Data must flow as fast as the metal itself.

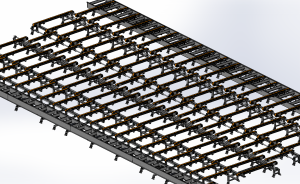

Pinrui’s automatic handling table production lines act as the nervous system of the plant. These systems integrate the belt-type cold bed with the main press PLC. The result is a fluid, continuous motion that eliminates the jerk-and-stop vibration common in legacy equipment.

Material Science: From Annealing to Age Hardening

The metallurgical journey does not end at the saw gauge. Post-extrusion heat treatment is where the final mechanical properties of the alloy are locked in. Understanding the difference between annealing and tempering is critical for engineers designing structural components.

Stability requires controlled heat. Our ageing furnaces provide a high-velocity air circulation environment that ensures ±3°C temperature uniformity. Whether you are producing age-hardened aluminum for aerospace or standard architectural profiles, this level of thermal precision is non-negotiable for long-term reliability.

Redefining Throughput with Intelligent Sawing Solutions

Precision at the start is wasted without precision at the finish. The final cut determines the assembly tolerances for the end-user, especially in modular construction. Even a 0.5mm deviation can render a batch of high-value profiles useless.

Pinrui’s finish saw and saw gauge systems offer a digital solution to physical waste. The system automatically calculates the optimal cut list to maximize yield from every billet. Combined with our automatic stackers, the entire backend becomes a hands-free operation.

The Future of the Extrusion Shop Floor

Digitization is no longer a luxury for the elite. As global demand for lightweight aluminium extrusion parts surges in the EV market, the margin for error has evaporated. The future belongs to those who can produce complex, curved aluminum extrusions with zero-defect consistency.

Synergy. Automation. Precision. These are the pillars Pinrui has built since 2009. If you are ready to transition from manual legacy systems to a fully integrated, high-precision environment, contact our engineering team today to discuss your custom layout.